Innovative river heat project in Wittenberge: climate-friendly district heating with HUBER ThermWin

The Wittenberge municipal utilities have set itself the goal of making the heat supply for the city in north-western Brandenburg and its surrounding districts largely climate-neutral by 2045. As part of municipal heating planning, various options for expanding and decarbonising the heating network are being investigated.

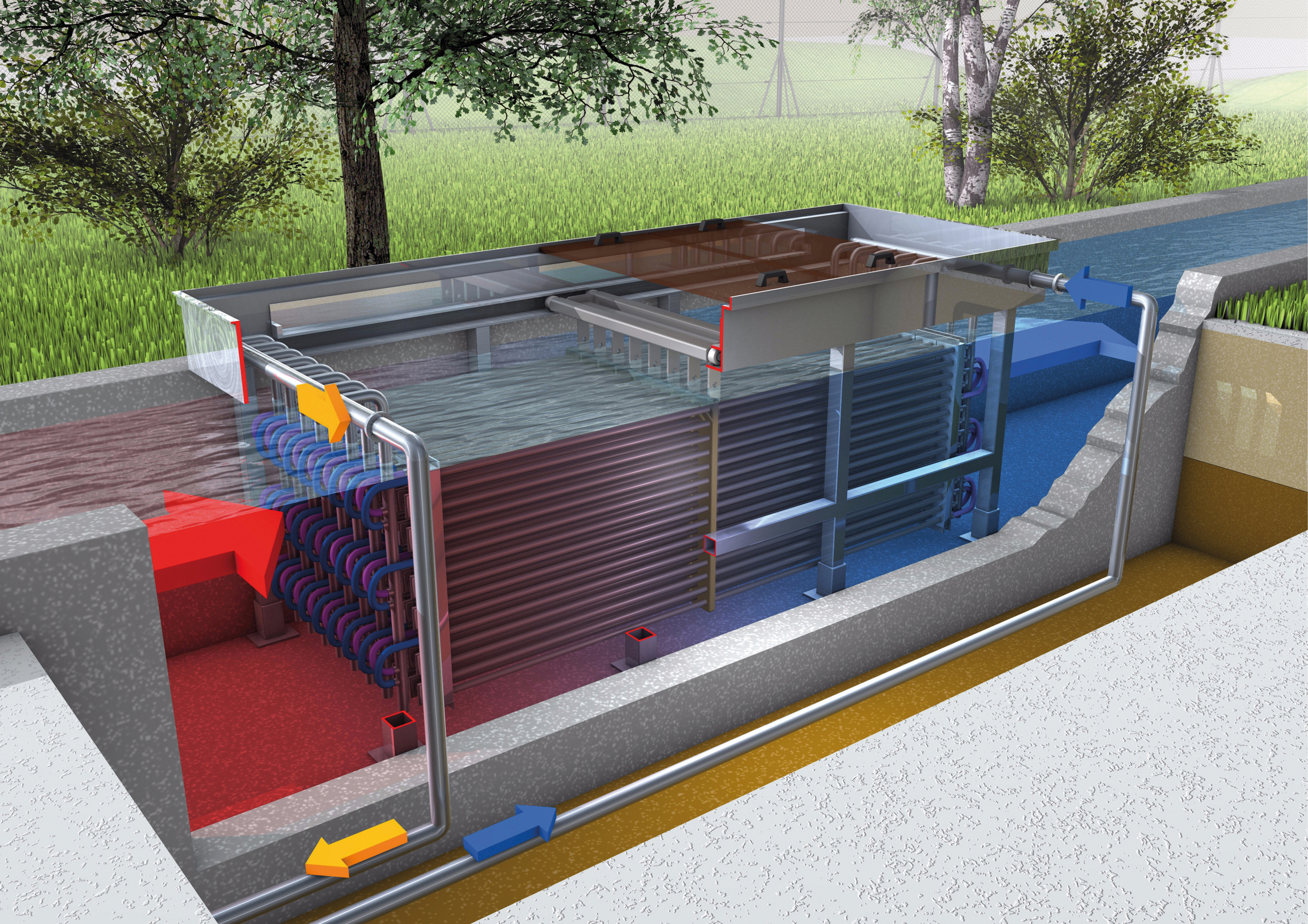

River water as a source of energy

A first step in this direction was completed at the end of last year with the construction of a new heating plant featuring a heat pump system, an electric boiler and a CHP unit. The heat pumps use water from the Stepenitz river as their energy source. The electrical power for this comes from the CHP unit.

However, due to the biological activity in the river water, the heat pump cannot be connected to it directly, as biofouling – the growth of microorganisms, plants, algae and animals on underwater structures – would impair the heat pump's performance and result in high maintenance costs.

HUBER Heat Exchanger RoWin14

The newly installed HUBER Heat Exchanger RoWin14 plays a crucial role in this process. By interconnecting the HUBER system, the energy from the river is first transferred to a clean medium, the heating water, enabling the heat pump to operate properly.

The process

To extract heat from the river, approximately 200 m³/h of water is diverted from the river through an outlet structure. This water is pre-cleaned using a drum screen before being pumped to the combined heat and power plant 270 metres away.

Fully automatic cleaning system

There, the HUBER Heat Exchanger RoWin14 transfers the heat to an intermediate circuit. Biofouling that forms on the wastewater heat exchanger surface is reliably and fully automatically removed by the patented cleaning system. This ensures that the designed output can be achieved.

The Carrier heat pump can use the river heat transferred to the heating circuit water as source energy, thus providing a heating capacity of approximately 1,100 kW. Up to 780 kW of this comes from the river.

The plant has been operating reliably since commissioning in 2024, supplying clean thermal energy to the municipal utilities' great satisfaction. Other municipal utilities have visited the plant and are evaluating the utilisation of river water heat based on the Wittenberge model.