Two new coarse screens for Villach sewage treatment plant: HUBER Multi-Rake Bar Screen RakeMax®

For many decades, the coarse screens designed as direct current screens served their purpose in the Villach sewage treatment plant, which has a capacity of 250,000 PE. During rainfall events, it often happened that the resulting amounts of screenings could no longer be conveyed because the single rake was unable to hold them. The reason for this was that the clearing interval lasted more than one minute – a circumstance that led to the accumulation of screenings in front of the screen during a flushing surge, which in turn often resulted in the collapse of the screening system.

Two screens with different requirements

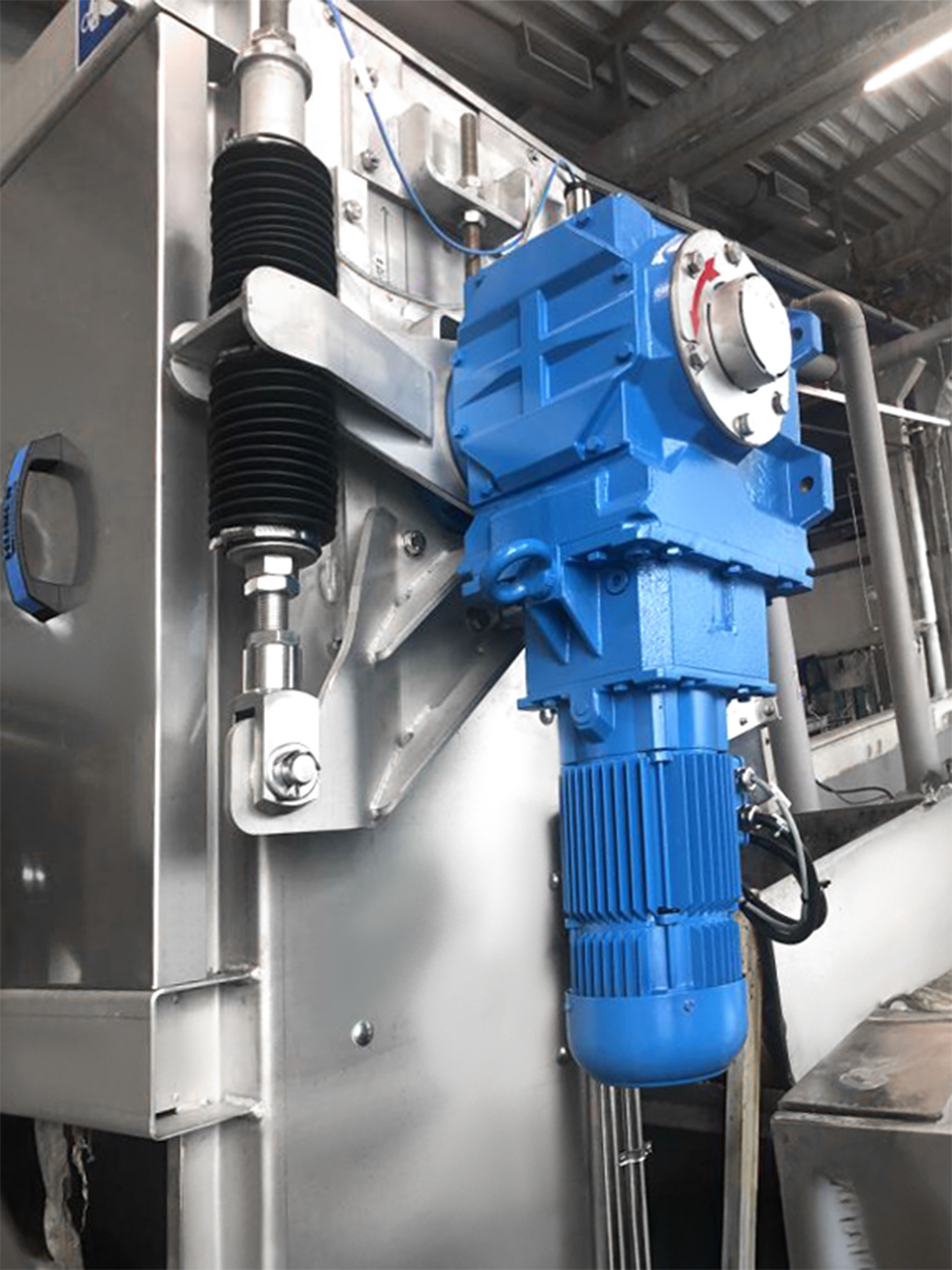

The requirement was to install two coarse screens with different bar spacings, 8 mm and 12 mm, and two different throughput rates of 1.8 and 5.4 m³/s in two existing channels 5.25 m deep and 2.5 m wide.

The HUBER RakeMax® impresses

HUBER impressed with the technical features of its Multi-Rake Bar Screen RakeMax®. The client was particularly impressed by the following features:

- the solid chain made of V4A steel with double breaking load, wider chain links and correspondingly low surface pressure in the joints

- the wide protective rollers for the large-diameter chain bushings

- the large chain pitch, which results in fewer joints and thus less chain wear

- the chain bushings and pins made of duplex steel

- the ceramic/chilled cast chain sprocket bearings in the lower chain deflection wheels, which had already proven themselves in thousands of grit washers, grit classifiers, screw conveyors and more than 3,000 RakeMax® screens worldwide, as well as in numerous HUBER Belt Screen EscaMax® units, thanks to their extremely high wear resistance.

Proven materials and reference projects strengthen confidence

For instance, after around 50,000 hours of operation, the lower ceramic/chilled cast iron sprocket bearings of the 3.0 m wide, approximately 1.5 m deep HUBER Belt Screen EscaMax® at the Salzburg wastewater treatment plant were removed. This screen was operated with a large water level difference. Despite having to withstand many times the load of a RakeMax® screen, the bearings showed no significant wear.

Being able to provide such references strengthens confidence.

Further design features for optimum performance

Two further features were:

- the low hydraulic resistance of the screen bars used by HUBER and

- their tangle-free spacer mounting halfway up the two-metre-high bar rack.

Adjustments for maximum operational efficiency

In addition, the RakeMax® coarse screens for this site were designed with three more clearing rakes than is standard manufacturing practice.

As the HUBER field service team has been familiar with the RoK installations in the storm water overflows for many years, special attention was paid to high clearing speed and thus low screen clogging.

Quality in detail convinces the operators

Some readers may find the above description overly detailed, but it is precisely this multitude of well-considered design features that are presented here: These features account for the HUBER Multi-Rake Bar Screen RakeMax®'s particularly high quality and reliability, a fact recognised by the managers of the Villach sewage treatment plant.

More information at www.huber-se.com/de-de/produkte/rechen-feinsiebe-feinstsiebe/harken-umlaufrechen/