HUBER plastics recycling solutions – operational experience and customer benefits

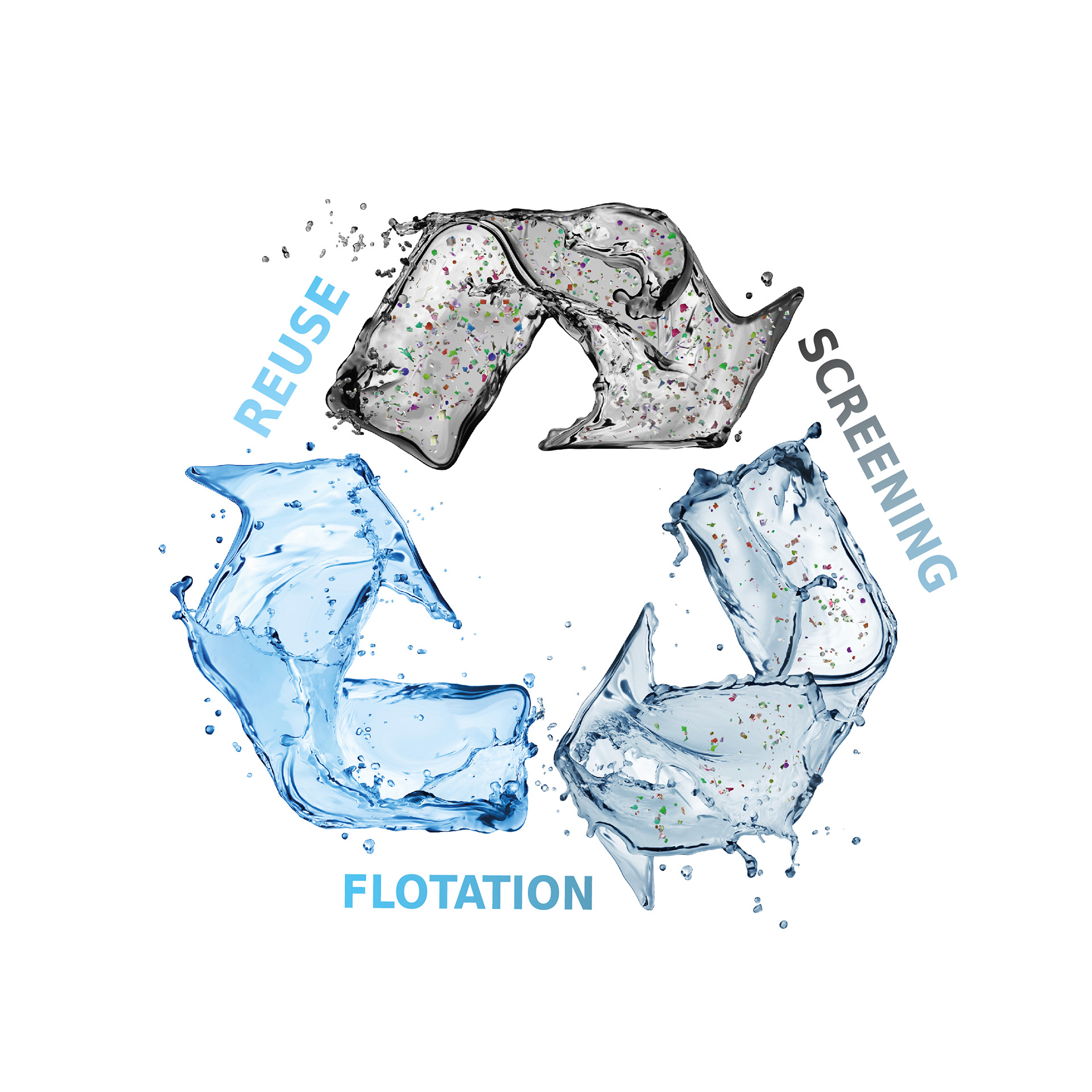

In times of global uncertainty, rising raw material prices and growing environmental requirements, the recycling of plastics is becoming increasingly important. However, producing new materials from fossil fuels is often still cheaper than recycling. This makes the quality of the recycled material and the cost-effectiveness of the entire plastic recycling process all the more crucial. This is precisely where HUBER comes in. Our technologies for treating process water and sludge provide the basis for sustainable and economical recycling processes.

Advantages of HUBER technology based on customer feedback

HUBER offers a comprehensive range of machines and plants for the treatment of process water and sludge, which is a major advantage over many competitors. This is a significant benefit for planners, consultants, and manufacturers of plastics machinery. They have a single point of contact, a specialist, who can cover all their water treatment requirements. The wide range of variants in the HUBER portfolio also enables high throughput rates with just one machine (e.g. 350 m³/h per flotation unit).

Highest quality and materials

HUBER relies on the highest quality stainless steel for its products and solutions, which are fully acid-treated in a pickling bath. This ensures durability and process reliability.

HUBER Global Service

Another key advantage is that HUBER offers global service through its subsidiaries, representative offices and partners, supported by four international production sites. This ensures rapid support even outside Europe.

Operating experience in plastics recycling

As one of many examples, a leading global manufacturer of high-performance plastic films relies on HUBER technology at several of its sites, including locations in Sweden and France. They recycle agricultural and construction films are recycled there.

HUBER machines used

- HUBER Complete Plant ROTAMAT® Ro5

- Reliably removes contaminants such as plastic particles and grit. Simultaneous compaction significantly reduces disposal costs.

- HUBER Dissolved Air Flotation Plant HDF with DIGIT-DOSE chemical dosing

- The clear water can be reused in the recycling process and as process water for the HUBER machinery. The intelligent DIGIT-DOSE system simultaneously reduces both precipitant consumption and sludge volume – a clear advantage over competing products.

- Throughput: 150 m³/h – one HUBER unit can replace up to three flotation units from other suppliers.

- HUBER Screw Press Q-PRESS®

- Fully automatic, continuous dewatering with minimal energy consumption (<1 rpm thanks to IE4 drive). In contrast to centrifuges or chamber filter presses, personnel costs, downtime and wear are greatly reduced. The press water produced is directly reprocessed via the HUBER flotation unit – a closed water cycle.

Customer satisfaction

Thanks to high efficiency and a single point of contact, the customer plans to equip future sites, including in the USA and Denmark, with HUBER machines.

Cooperation with manufacturer of plastic recycling machines

A manufacturer of plastic recycling machines relies on HUBER technology as standard for the treatment of process water and sludge.

Machines used:

- HUBER Drum Screen RoMesh®

- Removes fine solids from the process water. The integrated rinsing system enables operation without the need for any fresh water supply.

- HUBER Dissolved Air Flotation Plant HDF and HUBER Screw Press Q-PRESS®

- These machines deliver above-average results in terms of separation performance, operating costs and maintenance requirements. According to customer feedback, they are significantly more efficient than competing products.

Additional customer benefits

- Technical expertise remains with the respective experts

- Synergies in joint tenders

- Only one contact person for multiple processes

- Reliable on-site service through the HUBER partner network

- Most efficient flotation on the market

- Excellent filtrate quality

- Minimal personnel and maintenance costs

- Unbeatable after-sales support – global and fast

- High-quality design as the basis for long service life

Summary

HUBER offers the plastics recycling sector not only individual machines, but complete, well-thought-out solutions. Through high-quality technology, energy efficiency, a global service network and in-depth application knowledge, HUBER creates clear added value for machine manufacturers, operators and planners, while also making an important contribution to a sustainable recycling management.

Downloads