Key practical partners in the HypoWave+ research project: HUBER machines treat wastewater for agricultural reuse

Water is becoming an increasingly scarce resource, even in Germany. As climate change progresses, conflicts over water resources will continue to escalate, particularly in water-intensive agriculture.

As part of the ‘HypoWave+’ project, a resource-efficient hydroponic system for water reuse in regional vegetable production was installed and scientifically monitored for the first time in Germany in 2024.

Wastewater as a valuable resource for irrigation

’The special feature of the HypoWave system is that we obtain high-quality treated irrigation water from municipal wastewater, which completely replaces the need for fresh water. Compared to conventional agricultural irrigation, water resources can thus be used much more efficiently,’ says Prof. Dr. Thomas Dockhorn, project manager at the Technical University of Braunschweig.

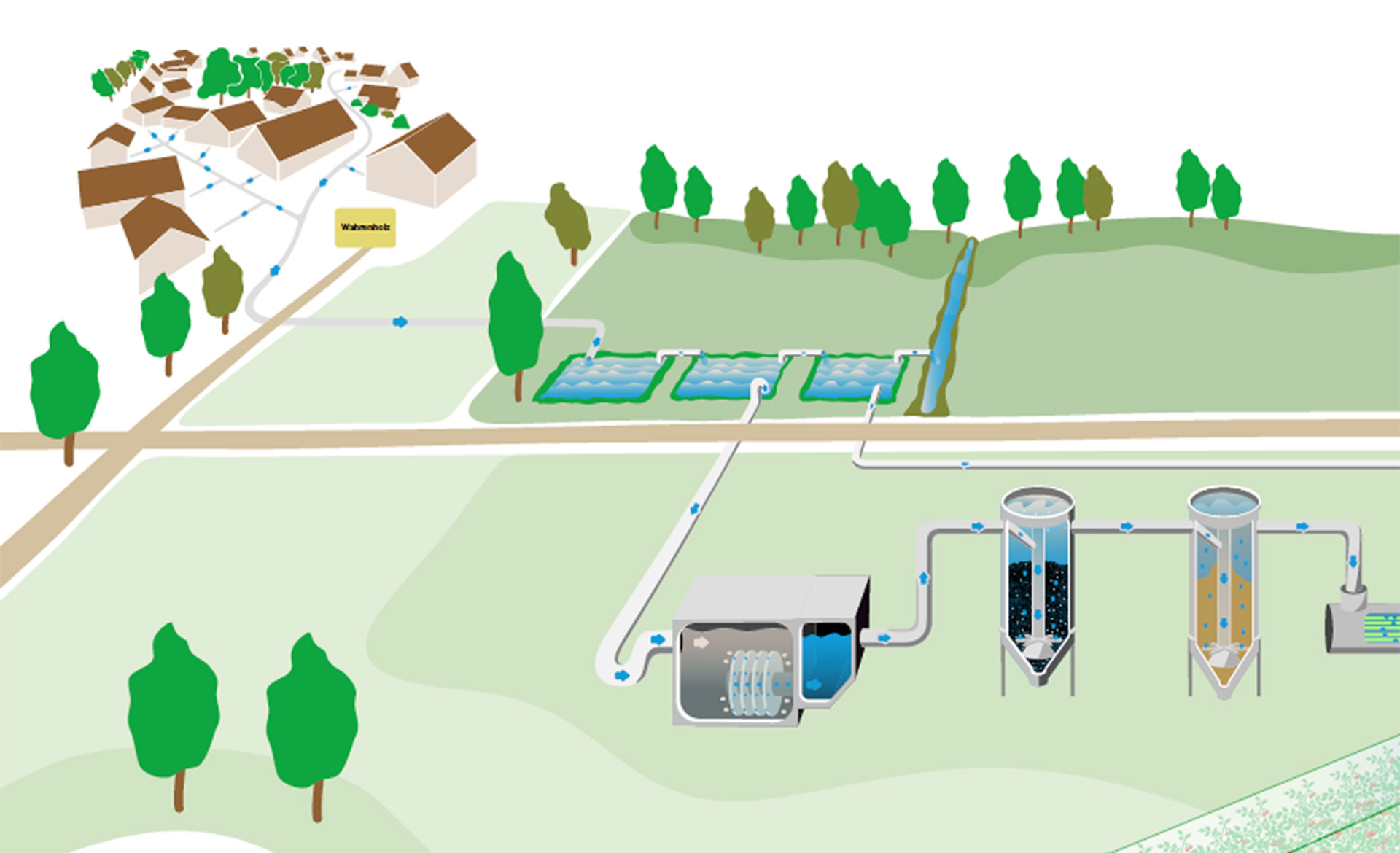

Multi-stage water treatment for the real-world laboratory in Weißenberge

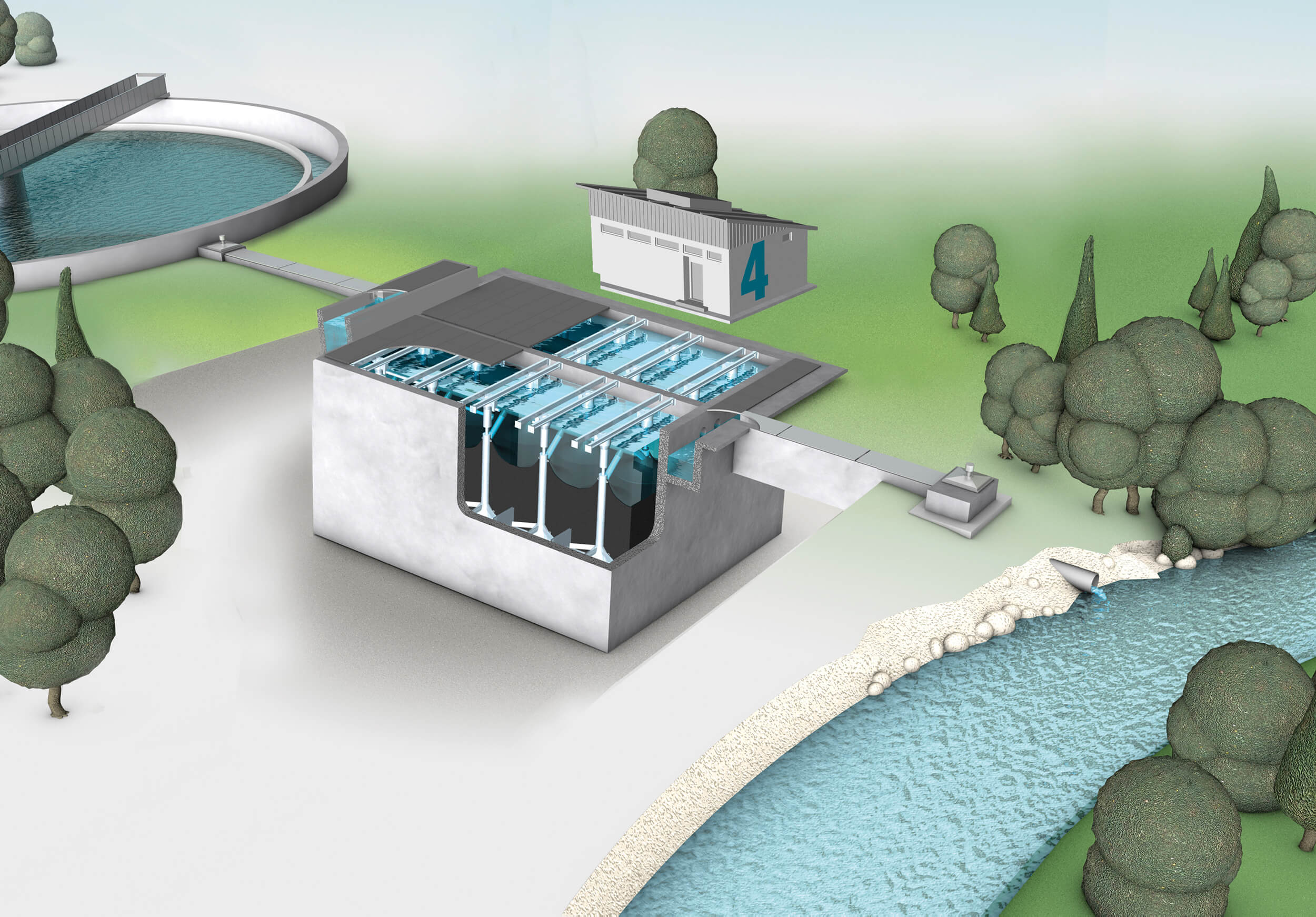

Since May 2024, the multi-stage water treatment system has been fed with effluent from the Weißenberge pond treatment plant. It consists of a HUBER Pile Cloth Media Filter RotaFilt® for retaining planktonic components and microplastics, a HUBER activated carbon biofilter for further trace substance elimination, and a HUBER Sandfilter CONTIFLOW® for retaining the last suspended solids from the biofilter.

A UV system from XYLEM (LBX 20) ensures reliable disinfection of the irrigation water before it enters the greenhouse. The entire treatment chain is designed for a throughput of up to 10 m3/h.

‘The excess water is highly purified when it flows back into the clarification ponds,’ explains Thomas Dockhorn. Nitrogen (Ntotal) in particular is depleted by the plants to up to 5 mg/l, which is well below the required monitoring values for sewage treatment plants.

Win-win for agriculture and water management

This makes cultivation with HypoWave water interesting for municipal operators of wastewater treatment plants who make their clarification ponds available for water reuse. ‘Cultivation in a greenhouse with purified wastewater in the vicinity of our ponds is completely new to us, but is already proving to be a win-win situation for agriculture and municipal water companies,’ says Christian Lampe, managing director of the Gifhorn Water Association.

Research benefits from the real-world laboratory character

‘The commissioning of the largest real-world laboratory of its kind to date and the cooperation with the municipal water association in Gifhorn is an extraordinary opportunity for research,’ says project coordinator Dr. Martina Winker from ISOE, Institute for Social-Ecological Research.

Validation and quality management

A central component of the research activities in 2024 was the validation of the water treatment process. To this end, all relevant approval processes relating to water reuse and the certification of the products produced were successfully completed as part of an integrated quality management system.

Safe water quality through regular laboratory analyses

To ensure compliance with the requirements set out in the EU regulation on water reuse, water samples were taken twice a week at the transfer point from the water treatment plant to the water storage facility and analysed immediately in the accredited laboratories of Eurofins and the Braunschweig Wastewater Association.

Excellent results confirm system efficiency

Regular laboratory analyses impressively demonstrate that the required quality class B can be reliably guaranteed at all times. In terms of the parameters BOD5, filterable solids, turbidity and E. coli, all samples even fully comply with the requirements for the monitoring parameters of quality class A.

The results thus clearly demonstrate the effectiveness of the technologies used to remove trace substances and microbiological contaminants and confirm the stability of the process over the entire test period.

HUBER would like to express its special thanks to the Federal Ministry of Education and Research (BMBF) for providing financial support for this promising research project. A big thank you also goes to all project partners, especially the Institute for Urban Water Management at the Technical University of Braunschweig and the Institute for Social-Ecological Research (ISOE) in Frankfurt for their excellent and constructive cooperation.

More information on the project at https://www.hypowave.de