Premiere of the HUBER Sludge Turner SOLSTICE® FloorRunner: new solar sewage sludge dryer in Kodersdorf

Kodersdorf in Saxony is located on the White Schöps River and is characterised by a charming landscape, nestled between the Königshainer Mountains and the Upper Lusatian pond landscape in the vicinity of Görlitz. The sewage treatment plant in the industrial area has a capacity of 7,500 PE and aerobic sludge stabilisation. The plant was expanded from 4,500 PE to 7,500 PE in 2023.

The expansion of capacity also necessitated the construction of a second sludge storage facility and a stationary sludge dewatering system. To ensure efficient sludge disposal for the future, the sewage treatment plant was equipped with a solar sludge drying system.

Premiere of the HUBER Sludge Turner SOLSTICE® FloorRunner

With this plant concept, the municipality of Kodersdorf is building a system that enables unmanned, autonomous operation thanks to full automation. The plant must be monitored, adjusted and maintained, but no personnel are required for actual operation. The entire process flow is automated, from thin sludge to dry granulate. Automation reduces the workload for operating personnel. In times of skilled labour shortages, the automated sludge treatment in Kodersdorf is therefore future-proof. The plant can be operated either directly via the HMI touch panels on the plant itself, or via screen redirection to on-site end devices.

Details of the process

Efficient sludge dewatering with the HUBER Screw Press Q-PRESS®

In Kodersdorf, a HUBER Screw Press Q-PRESS® 440 dewaters almost 150 tonnes of dry matter to approx. 20–23% dry residue. The annual 730 tonnes of dewatered sewage sludge are conveyed by a HUBER Screw Conveyor Ro8 TSF to the solar sewage sludge dryer.

Optimal drying thanks to intelligent system design

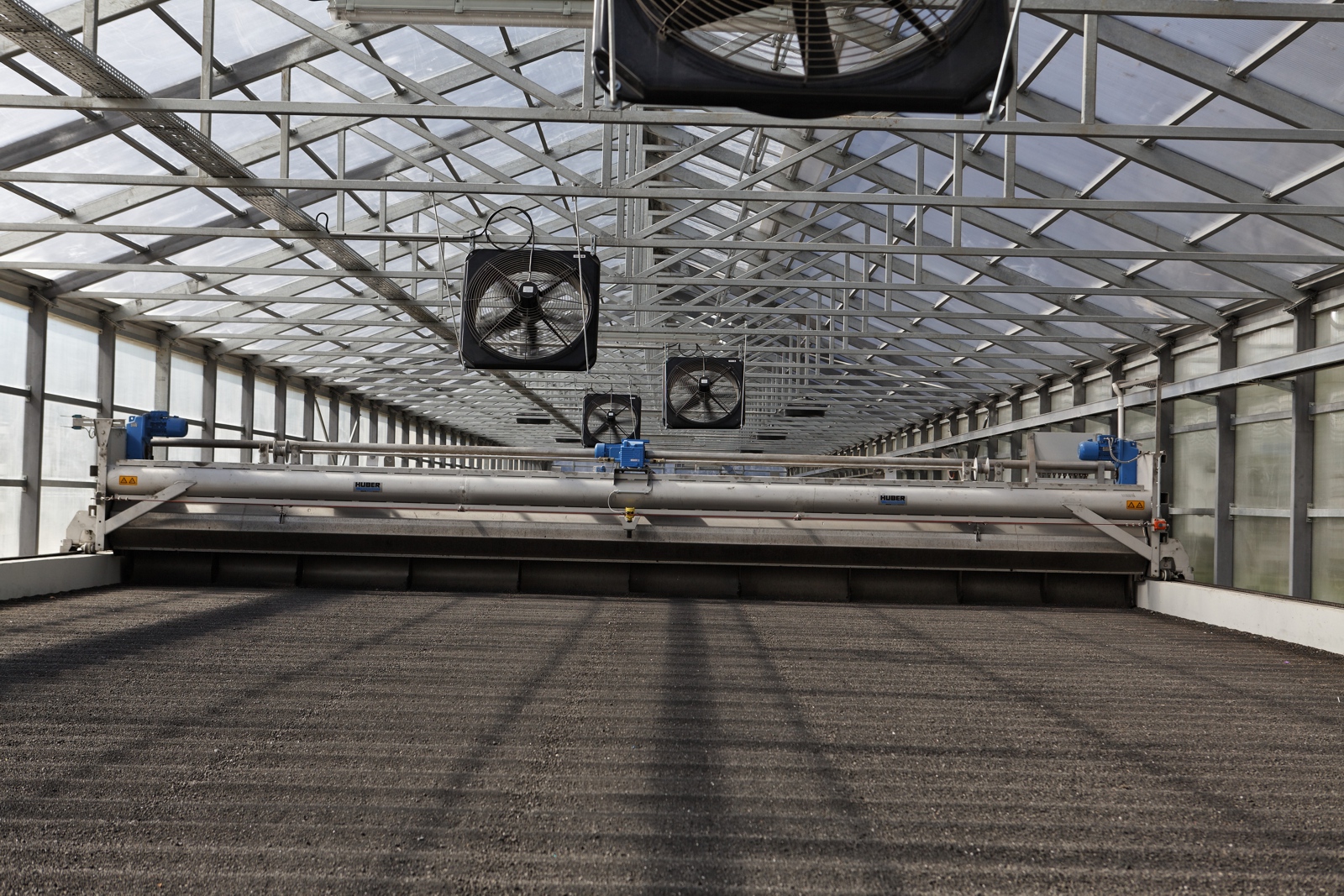

There, the HUBER Sludge Turner SOLSTICE® FloorRunner, which is movable on a newly developed steel angle construction, distributes the sludge over a 660 m² drying area. The drying area is housed in a 68 m long and 12 m wide greenhouse construction equipped with controlled fans. By turning the sludge with the HUBER Sludge Turner SOLSTICE® FloorRunner, combined with the air turbulence from the fans and the accumulated heat in the greenhouse, as well as direct sunlight on the surface, the sludge dries to an annual average of over 80% dry residue. With an annual global radiation of approx. 1,085 kWh/m²/a on site, 550 tonnes of water evaporate. At the end, approx. 180 tonnes of dry granulate with a density of approx. 0.8 kg/l remain to be disposed of.

Automated sludge removal for efficient further processing

The automatic sludge removal system, consisting in a HUBER Screw Conveyor TSD followed by a bucket elevator with distribution, conveys the granulate into two containers. Thanks to the consistent use of the HUBER machine technology, all components of the system are efficiently coordinated with each other.

Compactness and functionality through innovative technology

Like its predecessor, which required a concrete foundation, the HUBER Sludge Turner SOLSTICE® FloorRunner is equipped with a double shovel that turns the sludge bed and moves it forward. In order to move material to specific points, the sludge turner also uses the double shovel as a transport vessel. In Kodersdorf, this function is used to place wet sludge feeding and dry sludge removal on the same gable side of the greenhouse. This allowed the greenhouse construction to be extended to the boundary of the sewage treatment plant. The compact design makes optimum use of the available space.

HUBER Sludge Turner SOLSTICE® FloorRunner now available worldwide

HUBER now offers the SOLSTICE® FloorRunner worldwide. The benchmark status of solar sewage sludge drying with HUBER technology will become even more apparent in the future as the technology continues to develop. Long-term, trouble-free solar drying operation thanks to sophisticated HUBER machine technology will convince customers worldwide.

The commissioning of the plant was successfully completed in May 2025.

We would like to thank IBOS Engineering, ZV Kodersdorf and Stowasser for their excellent cooperation.

![[Translate to English (USA):] The Kodersdorf wastewater treatment plant, with a capacity of 7,500 PE, is the first solar sewage sludge drying plant to feature the new HUBER Sludge Turner SOLSTICE® FloorRunner [Translate to English (USA):] The Kodersdorf wastewater treatment plant, with a capacity of 7,500 PE, is the first solar sewage sludge drying plant to feature the new HUBER Sludge Turner SOLSTICE® FloorRunner](/fileadmin/user_upload/huber-technology/case-studies/sludge-thermal/25-08-floorrunner-kodersdorf/img-casestudy-25-08-erster-floorrunner-kodersdorf-01.jpg)

![[Translate to English (USA):] Solar sewage sludge drying with the HUBER Sludge Turner SOLSTICE® FloorRunner dries the sludge to an annual average of over 80% dry residue [Translate to English (USA):] Solar sewage sludge drying with the HUBER Sludge Turner SOLSTICE® FloorRunner dries the sludge to an annual average of over 80% dry residue](/fileadmin/user_upload/huber-technology/case-studies/sludge-thermal/25-08-floorrunner-kodersdorf/img-casestudy-25-08-erster-floorrunner-kodersdorf-02.jpg)

![[Translate to English (USA):] To ensure efficient sludge disposal for the future, the Kodersdorf sewage treatment plant was equipped with a solar sludge drying system [Translate to English (USA):] To ensure efficient sludge disposal for the future, the Kodersdorf sewage treatment plant was equipped with a solar sludge drying system](/fileadmin/user_upload/huber-technology/case-studies/sludge-thermal/25-08-floorrunner-kodersdorf/img-casestudy-25-08-erster-floorrunner-kodersdorf-03.jpg)

![[Translate to English (USA):] The HUBER Sludge Turner SOLSTICE® FloorRunner is equipped with a double shovel that turns the sludge bed and moves it forward [Translate to English (USA):] The HUBER Sludge Turner SOLSTICE® FloorRunner is equipped with a double shovel that turns the sludge bed and moves it forward](/fileadmin/user_upload/huber-technology/case-studies/sludge-thermal/25-08-floorrunner-kodersdorf/img-casestudy-25-08-erster-floorrunner-kodersdorf-04.jpg)