Surface water treatment at a waste disposal facility: a HUBER Dissolved Air Flotation Plant HDF treats wastewater for the Isar tributary

Quarzbichl, a material extraction and marketing company, provides municipal waste management services for the districts of Bad Tölz and Wolfratshausen. It also processes compost into high-quality soil on site.

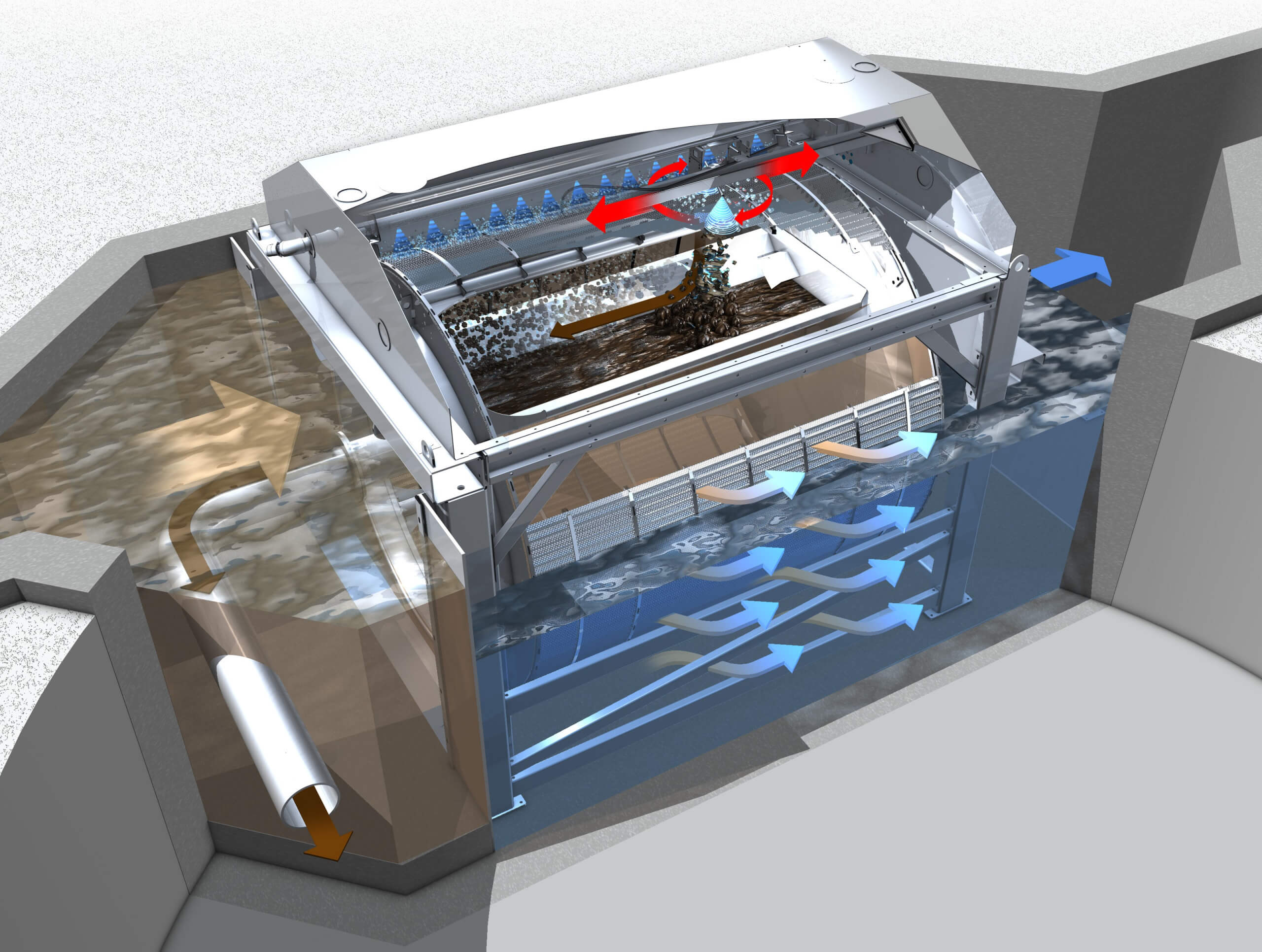

The surface wastewater produced is collected in an intermediate storage tank and treated for direct discharge into the Loisach River. The HUBER Dissolved Air Flotation Plant HDF process was chosen because the wastewater is almost exclusively contaminated with particles, the process effectively separates suspended solids from clear water without blockages, and the resulting residues are concentrated accordingly.

Pilot project as proof of feasibility

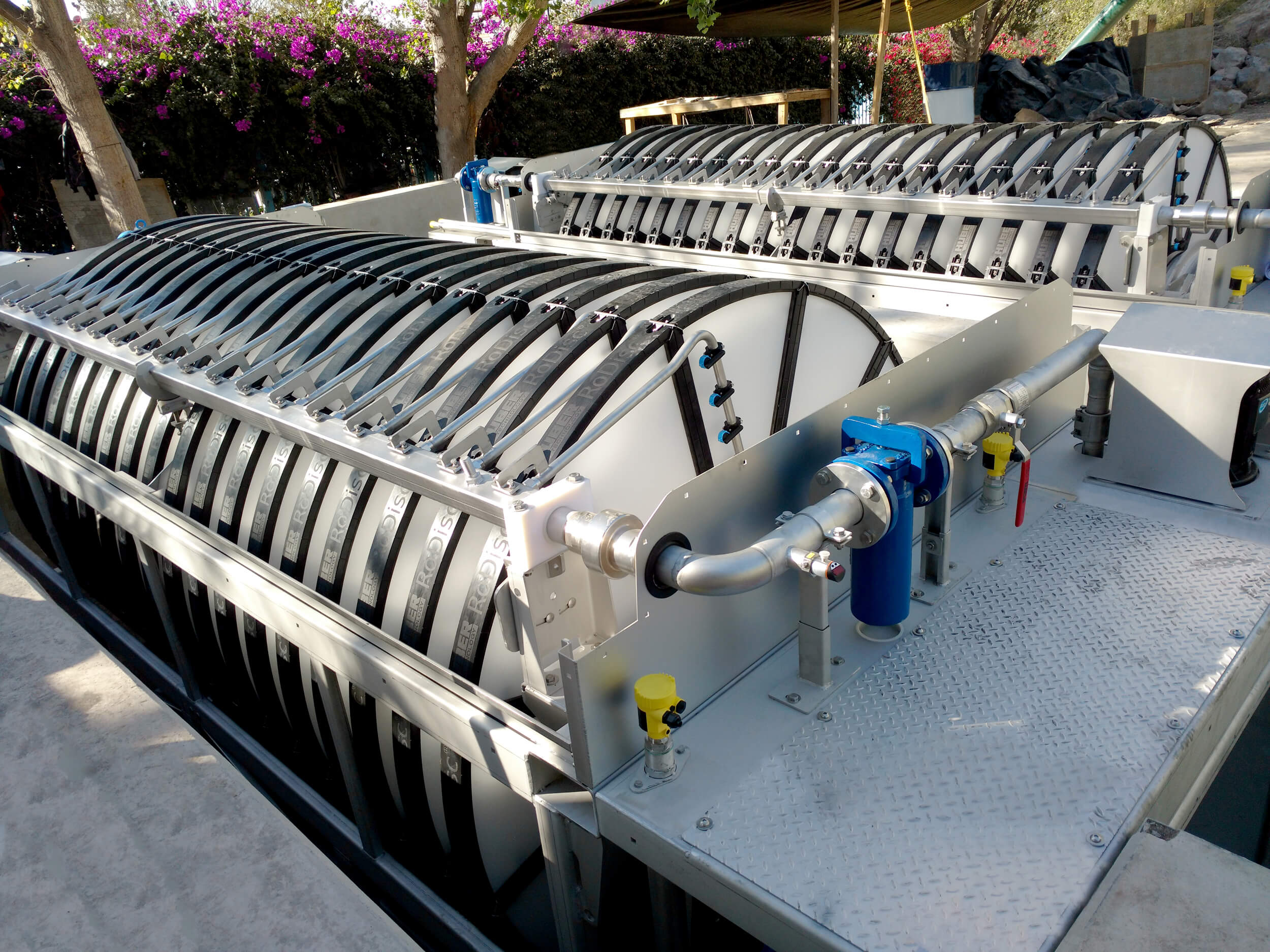

Every new process involves uncertainties and unknown effects by its very nature. To familiarize the future operator of the plant with the process and test its practical suitability, a pilot plant was installed. The plant was temporarily installed at the customer's site to demonstrate its effectiveness.

This pilot project enables a realistic estimate of future operating costs to be made. Specific cost factors, such as chemicals, are determined, enabling an economic assessment of the plant technology.

The plant's reliability under changing wastewater compositions is also thoroughly tested. Independent testing laboratories provide reliable data for the subsequent operation of the plant, and a qualified evaluation is carried out afterwards.

Transfer of results to permanent installation

Valuable insights counteract surprises: Based on these insights and results, the dimensions of the subsequent large-scale plant can be determined. The challenges encountered during the pilot operation are incorporated into the design of the large-scale plant.

In this project, an inline screen was installed as a so-called 'police filter’ as the first stage of treatment in the large-scale system to reliably retain coarse materials. The subsequent chemical stage was designed as a tube flocculator based on the findings of the pilot test.

It is important to note that drinking water-certified products must be used for chemical conditioning. This ensures that the flotate sludge produced later can be fed into natural composting within the company.

Wastewater treatment for the Isar tributary

In the flotation cell, solids are transported to the water surface by extremely fine gas bubbles. The remaining water is completely free of particles and can therefore be discharged directly into the receiving watercourse, the Loisach, a tributary of the Isar. Appropriate measurement technology is installed to monitor the water quality in the effluent and ensure that it remains consistently high.