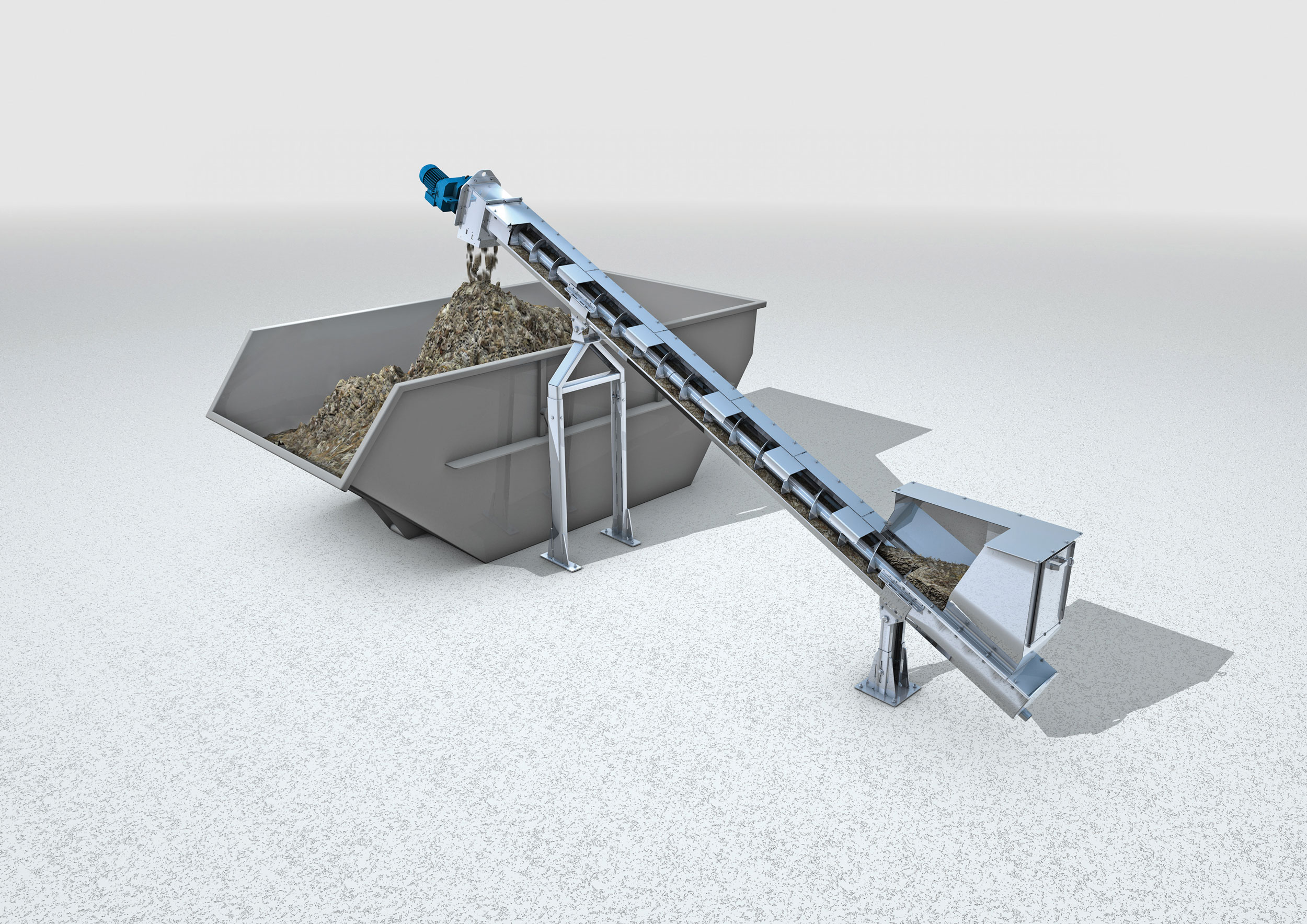

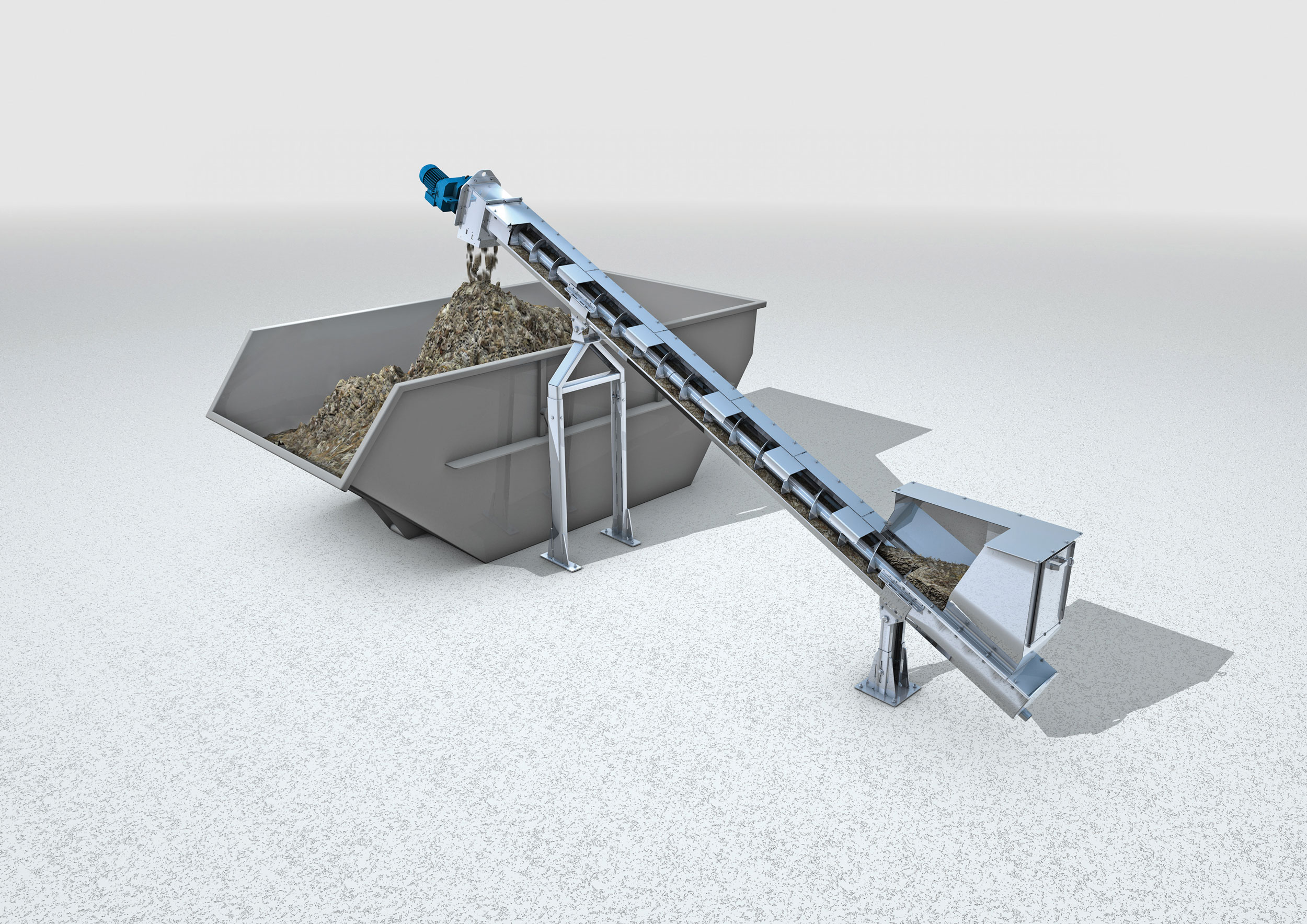

HUBER Lidded Trough Screw Conveyor Ro8 T Transport of coarse, fine and compacted screenings, sludge, grit, and solids

Design and Function

The HUBER Screw Conveyors are custom made for the individual product to be conveyed and designed and manufactured with state-of-the-art techniques. Due to their special design principle the conveyors can be equipped with either a push or pull drive and feed hoppers or discharges can be added if required. Direct screenings transfer from one to the other screw conveyor is no problem.

The trough version Screw Conveyor Ro8 T with its sturdy design and corrosion-free stainless steel components has plastic bearing shells that are fixed inside the trough. The equal distribution of the screw force over a defined cross-section minimizes bearing shell wear and reduces maintenance costs. The modular design permits easy disassembly.

Screw lengths up to 30 m for throughputs from 1 m³h to 12 m³/h are available with a screw installation angle of 45°.

Model variations

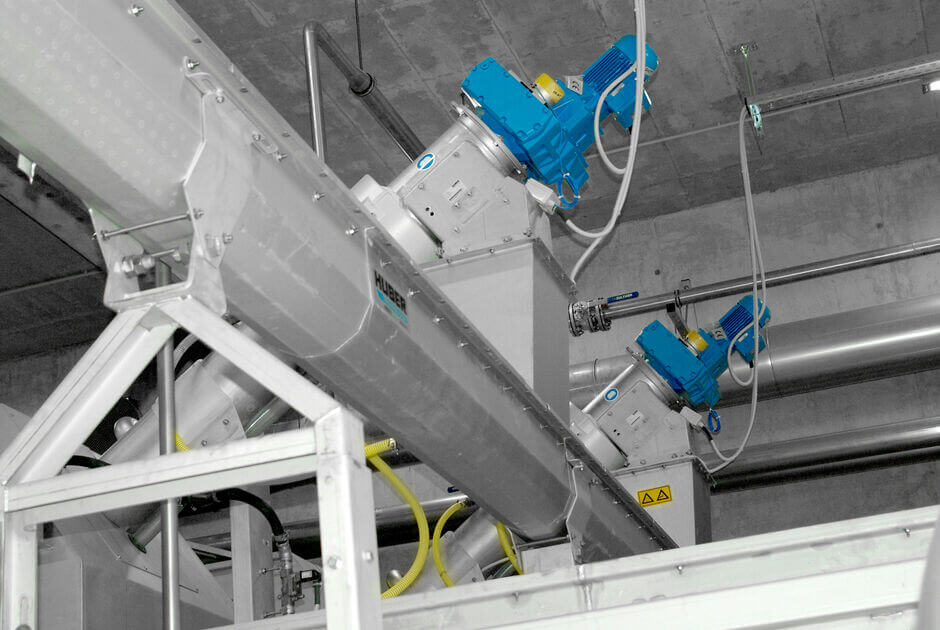

HUBER Double Screw Conveyor Ro8 T2

The HUBER Double Screw Conveyor Ro8 T2 is designed horizontally or at an angle and in different screw diameters depending on the desired delivery rate. The double screw conveyor is used for transport of screenings and dewatered sludge from wastewater treatment plants, or other waste from industrial processes. The entire transport process takes place in two troughs, which are filled with conveyed material by a double trough guide. Gentle movement in an enclosed pipe prevents odour nuisance and dust development.

The HUBER Double Screw Conveyor Ro8 T2 is custom made for the individual product to be conveyed and designed and manufactured with state-of-the-art techniques.

HUBER Screw Conveyor Ro8 TC as Distribution Screw

The HUBER Screw Conveyor Ro8 TC is used Screw Conveyor Ro8 TC for the transport and distribution of dewatered sludge, e.g. after the HUBER Screw Press Q-PRESS®.

The screw conveyor is designed with a swivelling system to enable the sludge to be distributed into several containers. A swivelling chute is fitted at the end of the screw conveyor to ensure that the cone is evenly distributed.

The entire process of material transport takes place within a lidded trough. The HUBER Screw Conveyor Ro8 TC is custom made for the individual discharge situation and designed and manufactured with state-of-the-art techniques.

The Benefits of the HUBER Lidded Trough Screw Conveyor Ro8 T

- Installation angle

Depending on application and layout, a screw installation angle up to 45° can be realised. - Completely made of stainless steel

The machine is completely made of stainless steel and pickled in an acid bath which eliminates corrosion and thus reduces maintenance. - Enclosed system

Gentle movement in an enclosed pipe prevents odor nuisance and dust development.

- Outdoor installation

For outdoor installations, the Screw Conveyor can be supplied with a frost protection, combined with an additional insulation if required. - Low maintenance

No lubrication. Regular checking and visual inspection are sufficient.

Downloads

![[Translate to English (GB):] HUBER Screw Press Q-PRESS® 620.2 with polymer conditioning plant. [Translate to English (GB):] HUBER Screw Press Q-PRESS® 620.2 with polymer conditioning plant.](/fileadmin/user_upload/huber-technology/case-studies/sludge-mechanical/24-06-qpress-beilngries/img-casestudy-24-06-qpress-beilngries-02.jpg)