COD, Fat and Solids Reduction for Industrial Wastewater

PROCESS TECHNOLOGY

HUBER solutions to reduce COD, fat and solids in industrial waste water

Part of this industrial pretreatment is usually:

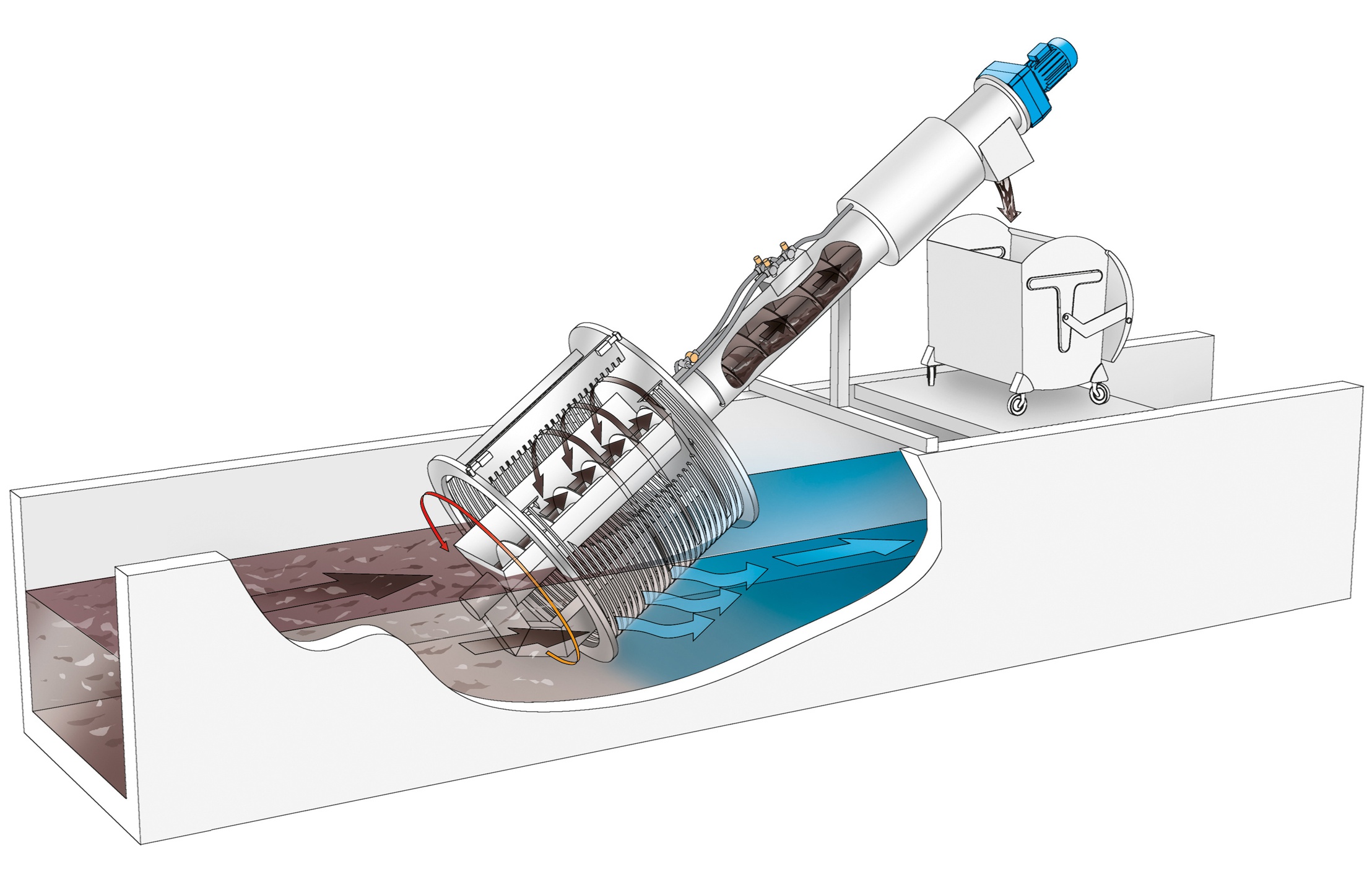

- Screens for mechanical preliminary treatment

- Grit traps (where grit is present)

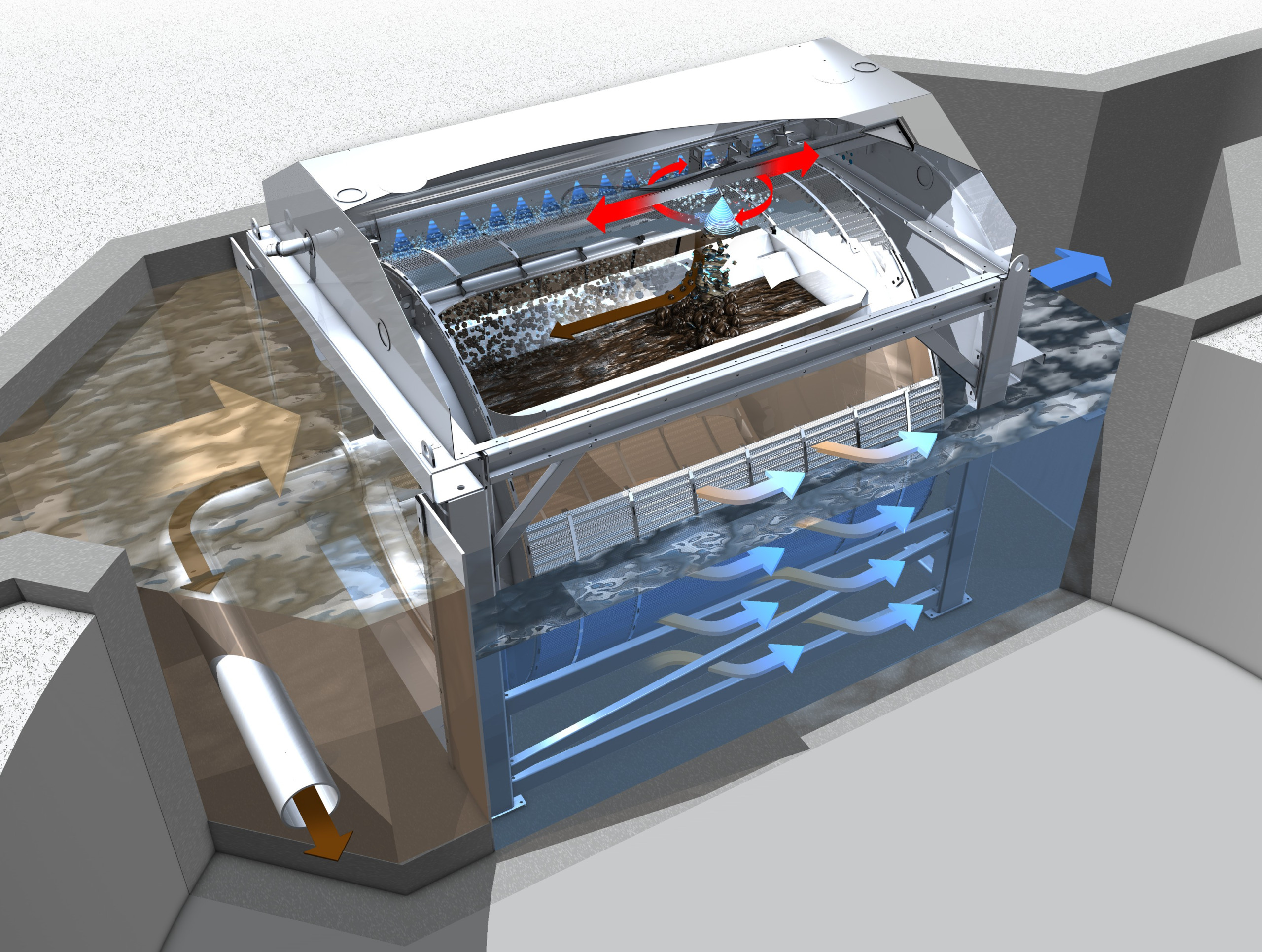

- Dissolved air flotation plants with chemical treatment stage

- Sludge treatment for resulting flotate sludge

Depending on the industry sector, type of wastewater and degree of contamination, the right machines and components have to be selected, as for example high grease contents require screen cleaning with high pressure or hot water.

HUBER has decades of experience in dimensioning and selecting the optimum machine technology for each industry wastewater pre-treatment application. As different requirements also demand different types of systems, HUBER has developed a wide range of various screens, fine screens, flotation plants and sludge treatment systems, which are in use in thousands of installations worldwide.

Separated and compacted screenings and grit are disposed of, while separated flotate (= organics) is usually further utilised in anaerobic sludge treatment as co-substrate or in approved biogas plants.