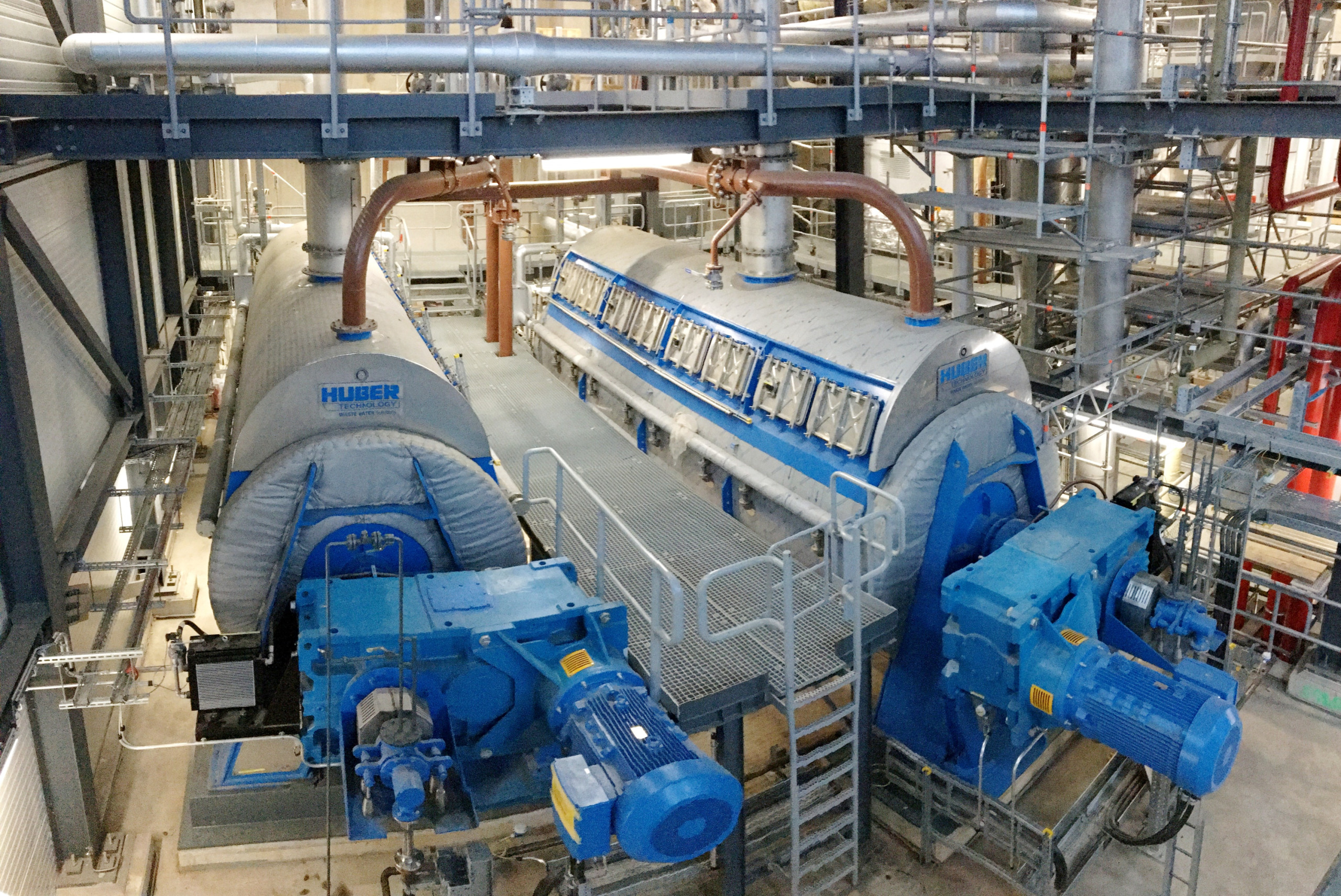

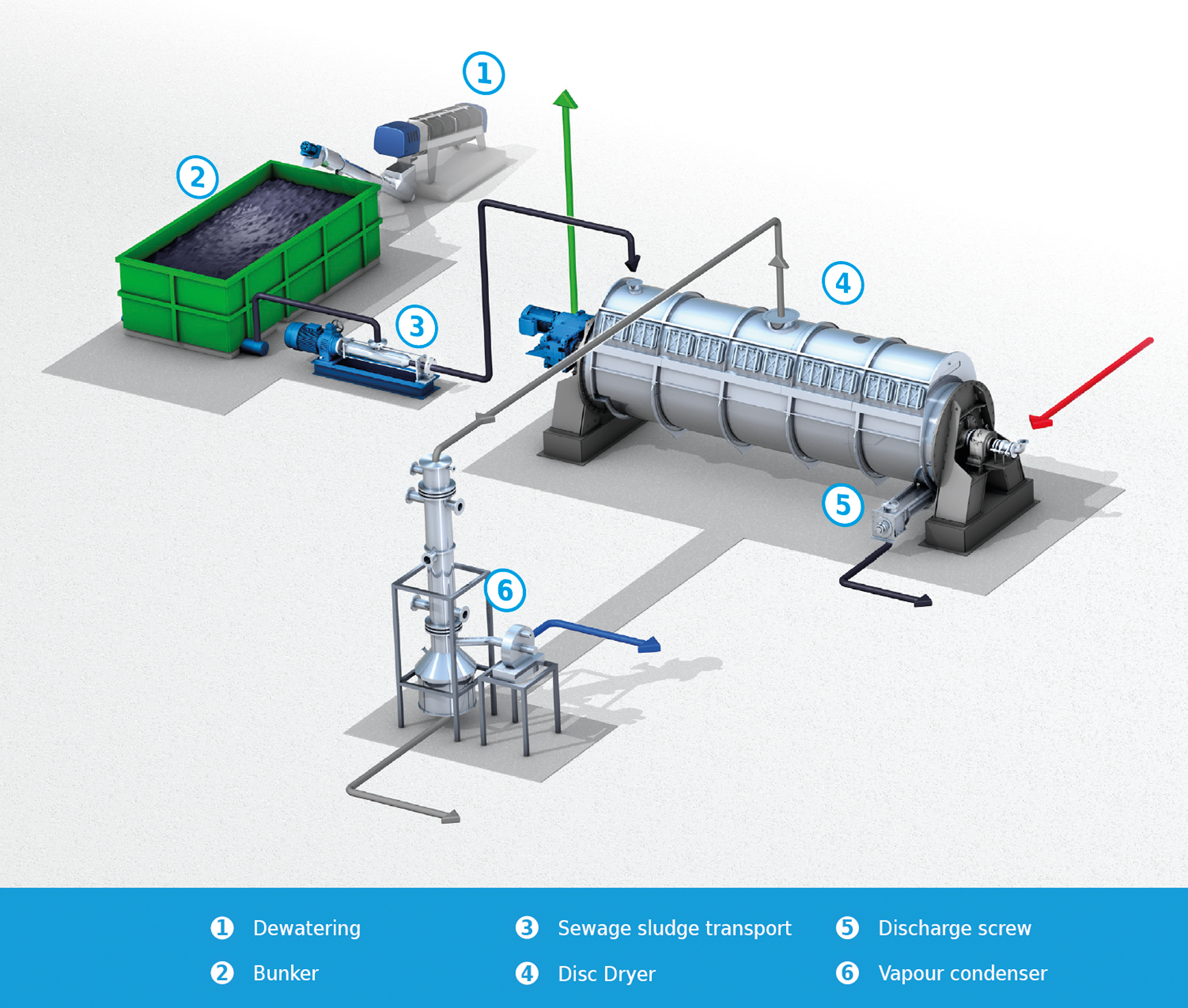

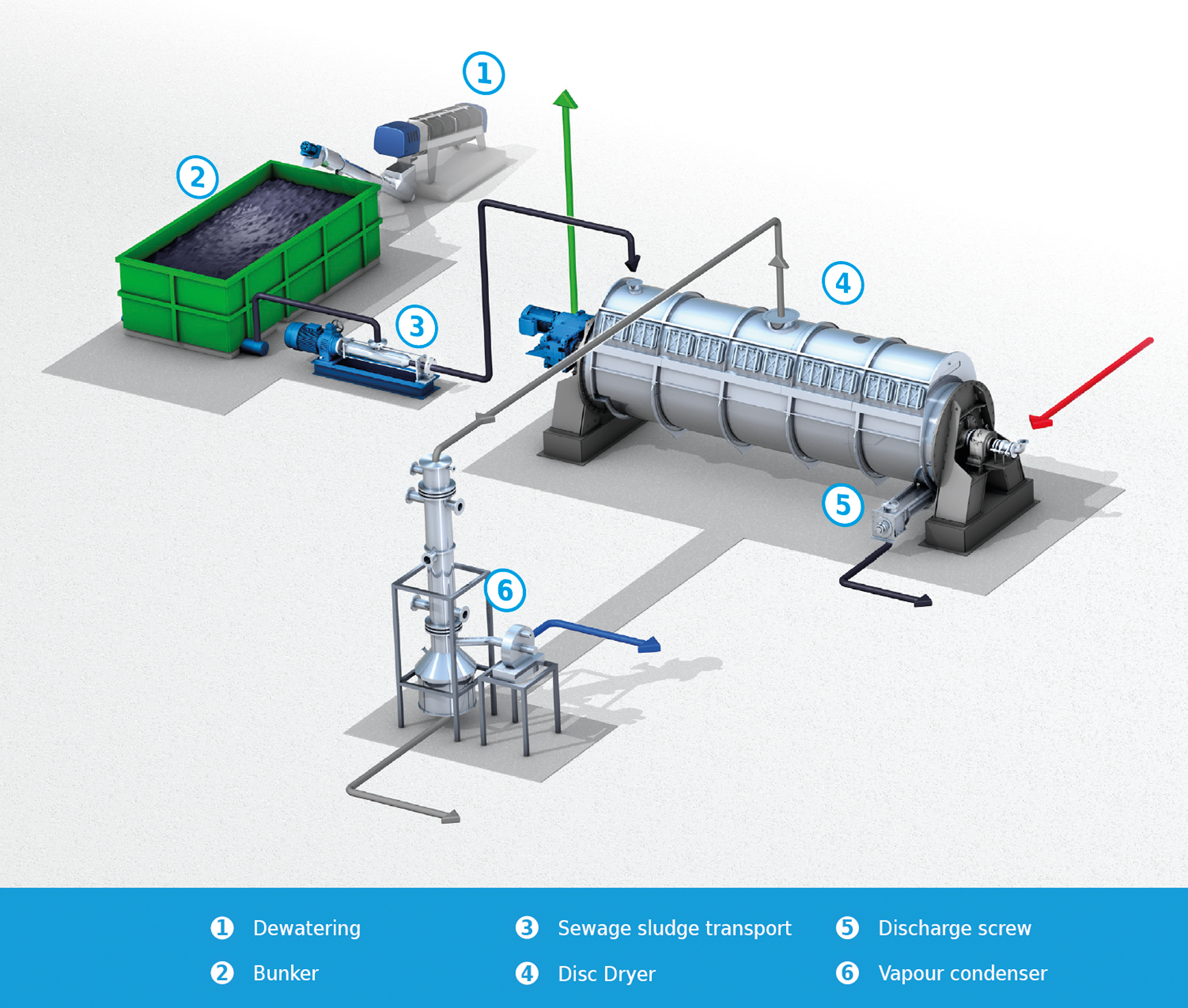

The RotaDry® disc dryer can be used in existing plants as well as for the new construction of a sewage sludge incineration plant. The sludge to be dried must comply with the HUBER sewage sludge specification for the disc dryer. Ideally, it should be well-stabilised municipal sewage sludge.

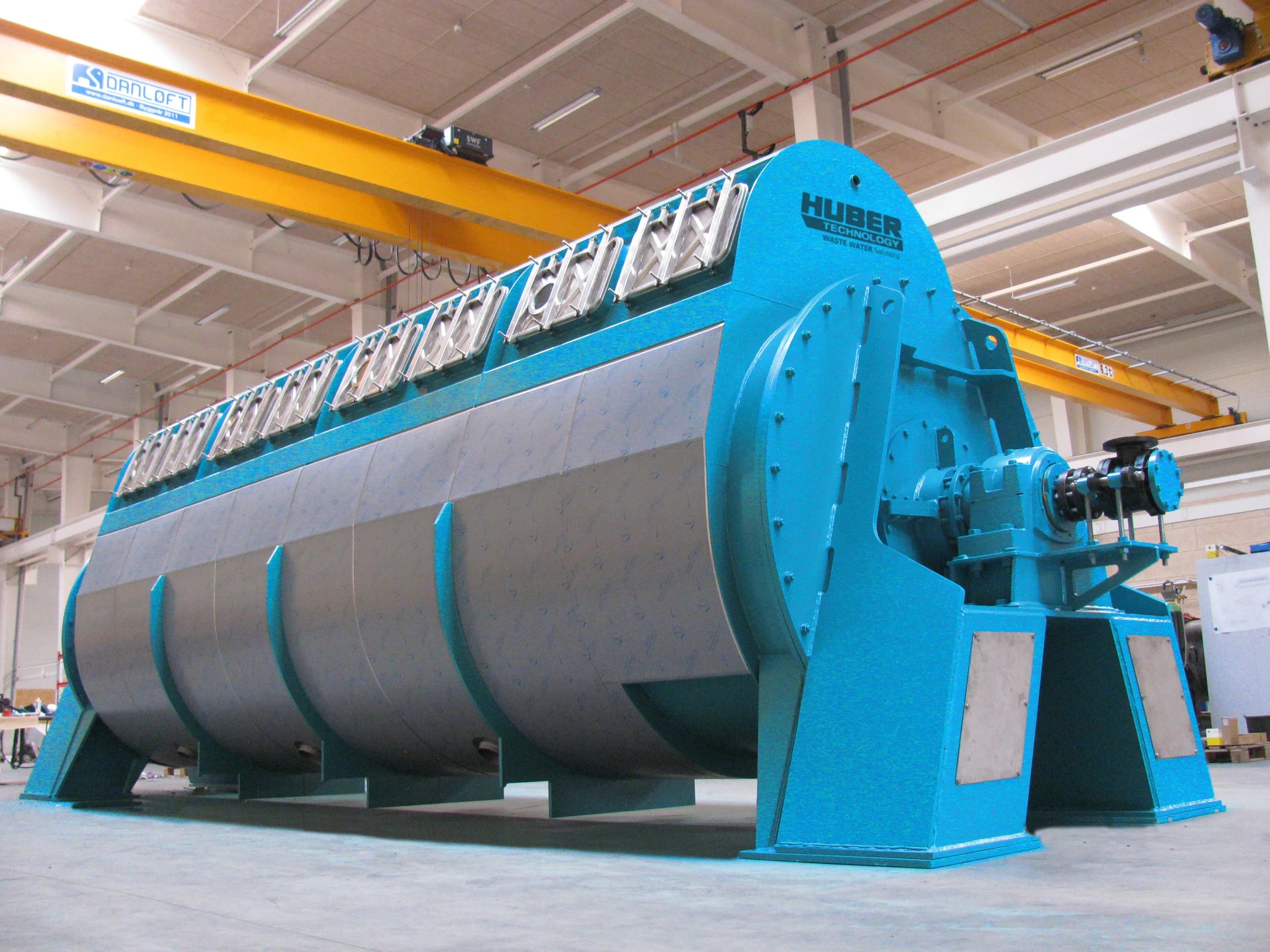

HUBER Disc Dryer RotaDry® Partial contact drying of sewage sludge for recycling in fluidized bed incineration plants

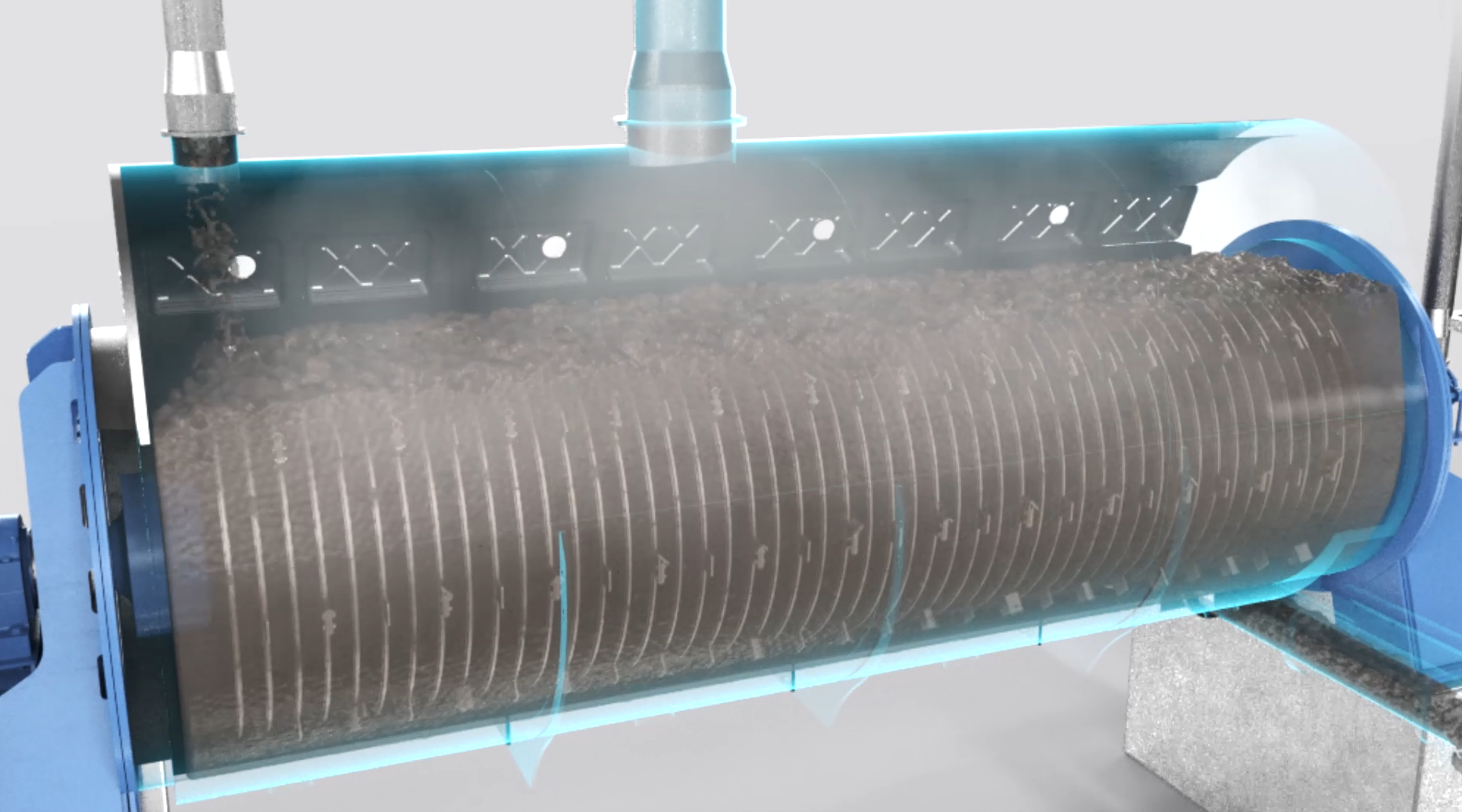

Design and Function

The HUBER Disc Dryer RotaDry® is designed for homogeneous partial drying of dewatered sewage sludge. Due to its compact design and high specific water evaporation, it is not only ideally suited for use in new sewage sludge mono-incineration plants, but also for capacity expansions of existing plants. The dryer can dry exactly to the required DR content and thus enable a selfsustaining combustion in the fluidized bed incinerator.

The HUBER RotaDry® is available in different sizes, so that a water evaporation of about two to six tons per hour and dryer can be achieved. By using different disc diameters and numbers of discs, the heating surface can be optimally adapted to the amount of generated sludge and the dryer can be operated in the ideal capacity range.

The heat requires for drying is provided and, depending on the size of the plant, electricity is also generated by means of steam turbine.

A reliable condensate removal system, an innovative concept for moisture control, an optimized feed and a steam control line with minimized pressure loss characterize the HUBER Disc Dryer RotaDry® as the perfect sewage sludge dryer in combination with a monoincineration plant.

All dryers are optionally available with jacket heating.

Vapour condensation

The overall dryer system always includes the condensation of the vapours produced by the disc dryer. Depending on the project-specific conditions, there are various possibilities here.

- Tube bundle condenser (indirect condenser)

Compact design to maximise the extraction steam for district heating, as heating water is raised to the required temperature level directly in the condenser. - Injection condenser (direct condenser)

Circulating and cooled vapour condensate is sprayed in the head of the condenser to knock down the condensable vapours. Robust and universal design. - Multi-stage condensation system

Consisting, for example, of a sludge preheater (for energy optimization and polymer consumption reduction in the dewatering process) and an injection condenser as residual condenser.

Steam and condensate system

In order to operate the dryer as efficiently as possible, the use of saturated steam is essential. Depending on the concept in the water-steam cycle, steam cooling is therefore necessary in addition to steam pressure control. Due to the ideal configuration of the controlled system. Both pressure-loss-minimized operation at nominal load and reliable regulation to the required steam pressure can be achieved. Even after it has passed the dryer, the liquid steam condensate does not remain energetically unused and is returned to the water-steam system. It is advisable to utilise the flash steam.

Vapour condensate treatment

Due to the high contact temperatures of the disc surface and sewage sludge, a high load of ammonium as well as particulate and dissolved COD (Chemical Oxygen Demand) is produced in the vapour condensate, which does not allow for immediate indirect discharge into the municipal sewage network and requires separate treatment on request, HUBER SE can develop a project-speficic solution for the treatment of the vapour condensate.

Ease of maintenance disc dryer

Maximum reduction of the activities during walkarounds

- The main rotor bearings and the discharge screw bearings are supplied with automatic grease lubrication.

- Highly efficient direct drive with peripheral speed adjustment capability. Wear-optimised driving style and startup under load possible.

- Discharge screw is easily accessible and removable for replacing wear plates and screw spiral.

The benefits of the HUBER Disc Dryer RotaDry®

- Compact design

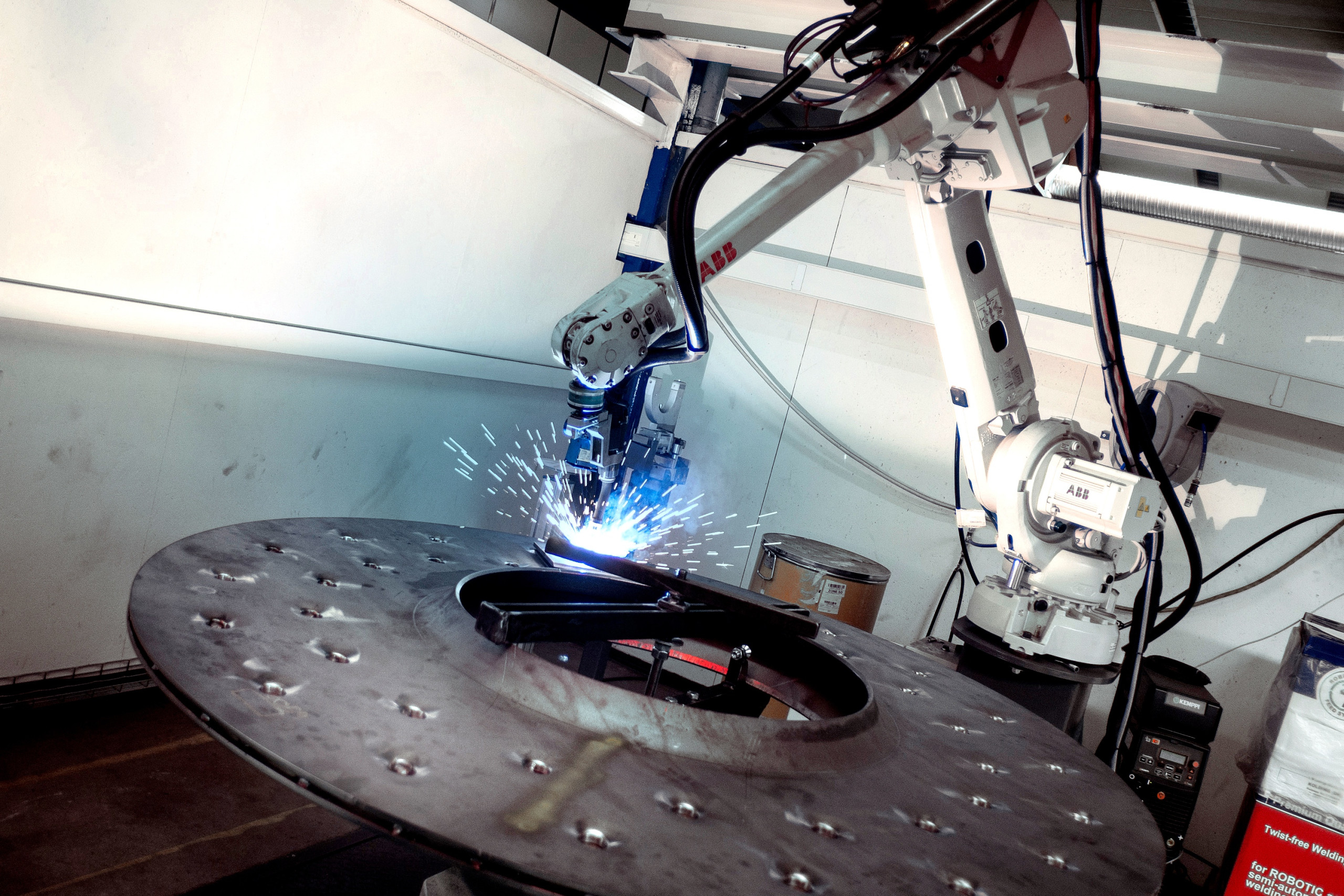

The HUBER Disc Dryer RotaDry® convinces by its compact design, which allows the dryer to be installed even on a small footprint or to be integrated into existing plants. - Proven and durable technology

The many years of successful use of disc dryers in combination with sewage sludge incineration plants demonstrate the robust technology of the process. - High specific water evaporation capacity

By heating the rotor discs and optionally the jacket, a high volume-specific water evaporation can be achieved. - Competent partner

Thanks to the cooperation between HUBER and OESTERGAARD, the customer is offered the best possible solution, both in terms of process and design.

- Maintenance-friendly dryer

Minimal effort for operating personnel thanks to automatic grease lubrication and low-maintenance direct drive. - Extended service life

By using a special welded construction for the discs, the minimum permissible residual wall thickness can be reduced. The service life of the rotor is thus extended to a maximum. - Control concept adapted to mono-incineration plants

In the event of fluctuating sludge quality, the DR measured online can be included in the control. - Secure condensate drainage

Reliable condensate drainage from the discs due to the omission of a syphon pipe.

Media

Videos and Animations

Downloads

Customer Information and Documents

FAQ