In order to be landfilled, the grit must be further treated before. Depending on the size of the sewage treatment plant and the amount of grit, grit classifiers or grit washers are used. The state of the art is now the grit washer.

HUBER Coanda Grit Classifier RoSF3 Grit separation and dewatering in one unit

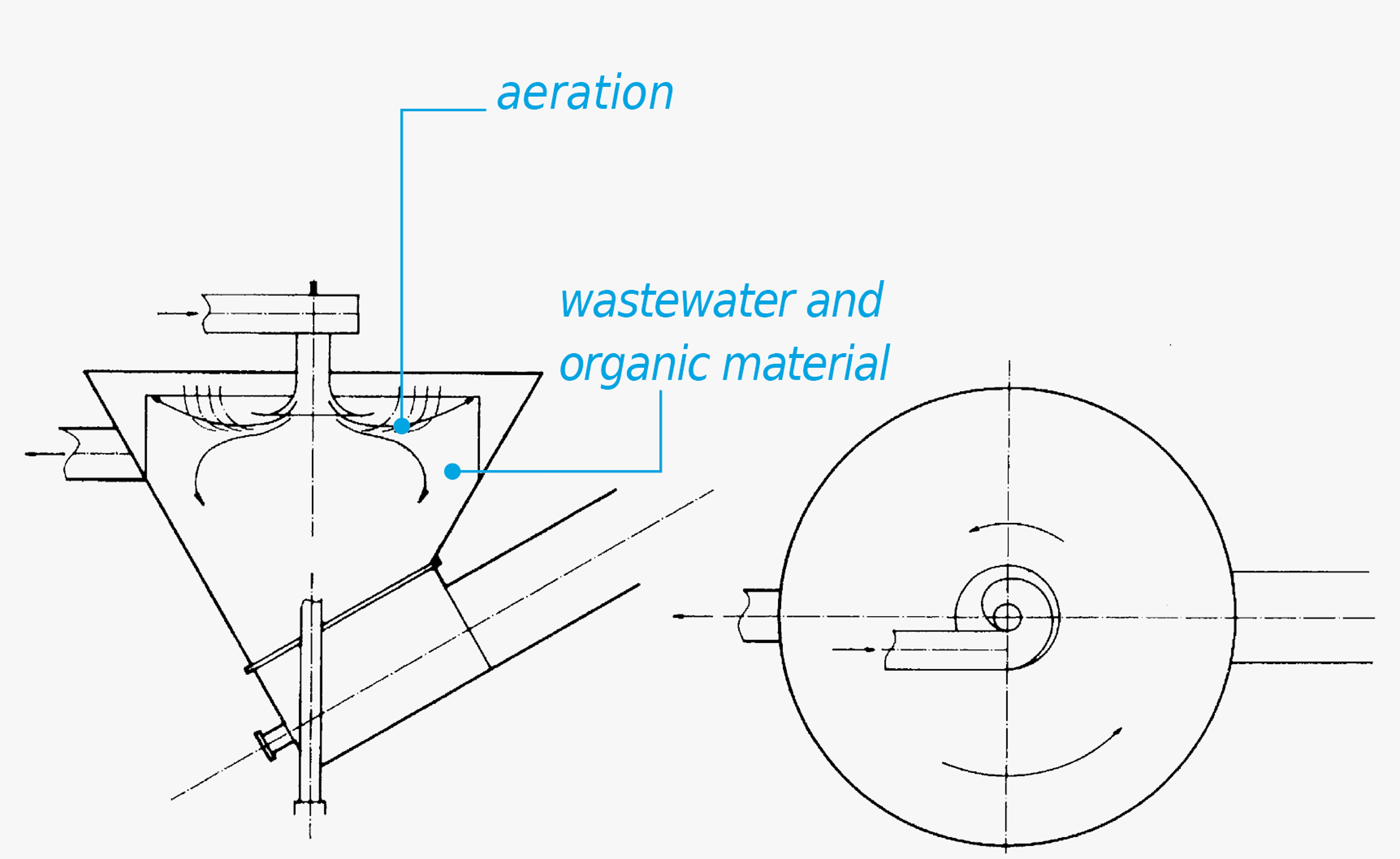

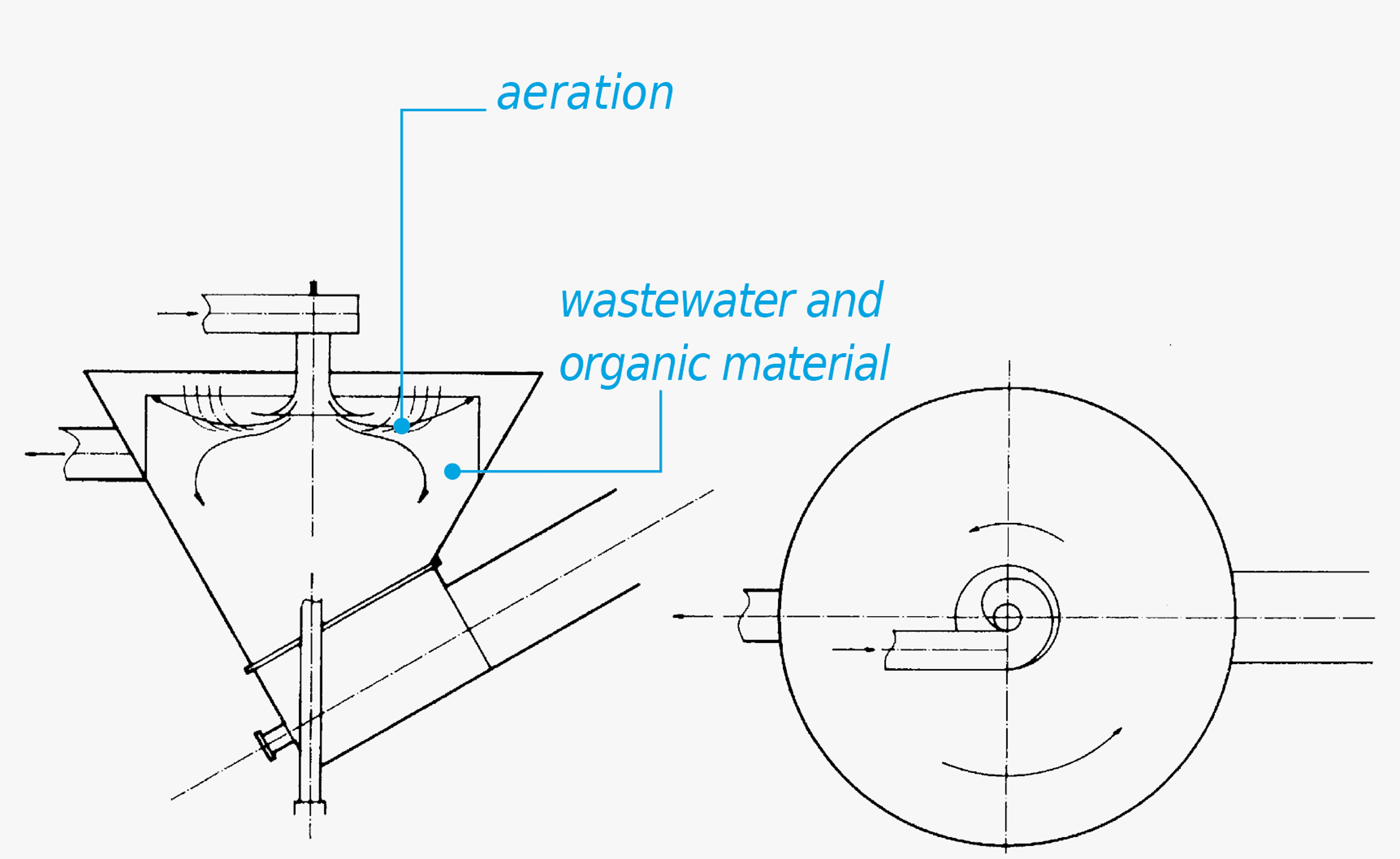

Design and Function

The difference in density between grit and other organic components can partly be taken into consideration to ensure reduced organic contamination and thus static dewatering of the classified grit. High efficiency has enabled the HUBER Coanda Grit Classifier RoSF3 to be significantly smaller than conventional classifiers.

The grit / water mixture flows either by means of a pump or by gravity into the vortex chamber where a rotary motion is induced. An automatic air intake takes place through the centrically located drilling hole on the vortex chamber.

The heart of the HUBER Coanda Grit Classifier RoSF3 is the inserted Coanda Tulip. The organically laden water flowing in from the top adheres to the tulip wall and is diverted to the horizontal below water surface by the Coanda-Effect. Reduced radial and tangential flows assist the separation process and the difference in density between organic and mineral material is partly taken into consideration.

The classifier screw transports the clean grit up an inclined plane where it is dewatered under gravity before discharge into a skip. The mineral residue from a plant operating under optimum conditions is in excess of 90% (e.g. a plant with appropriate pre-screening and grit collection facilities).

The benefits of HUBER Coanda Grit Classifier RoSF3

- High levels of grit separation of 95 % of grain size 0.20 - 0.25 mm

- Screw supported on both ends for minimised wear

- High corrosion resistance

- Encapsulated, odour-free plant

- Option of frost-proof design

Downloads

Customer Information and Documents

FAQ