With suitable wastewater heat exchangers (e.g. HUBER Heat Exchanger RoWin) the heat potential can be used for heating or cooling. Due to the contaminants and organic matter present, self-cleaning of the heat exchanger is elementary for reliable operation. In combination with heat pumps, the temperature level can be increased or reduced.

Reduce Operating Costs for Wastewater Treatment

Process Technology

HUBER solutions for reduction of operating costs

Regular evaluation of the plants often reveals a wide range of optimisation and cost-saving potentials:

- Optimisation of the mechanical preliminary treatment system

- Installation or optimisation of chemical-physical wastewater treatment

- Installation or optimisation of secondary treatment (filtration, flotation)

- Use of wastewater heat

In principle, the more solids and organic matter that can be removed by mechanical and physico-chemical processes, the lower the operating costs of wastewater treatment. In contrast, aerobic treatment is significantly more expensive because of the energy costs. In case of high amounts of dissolved organic matter, anaerobic treatment may also be useful.

HUBER has suitable machine technology and long experience in industrial wastewater treatment. Thus, previously undiscovered potential for improvement can be uncovered. Prior laboratory and pilot tests are used to determine the potential very precisely in advance.

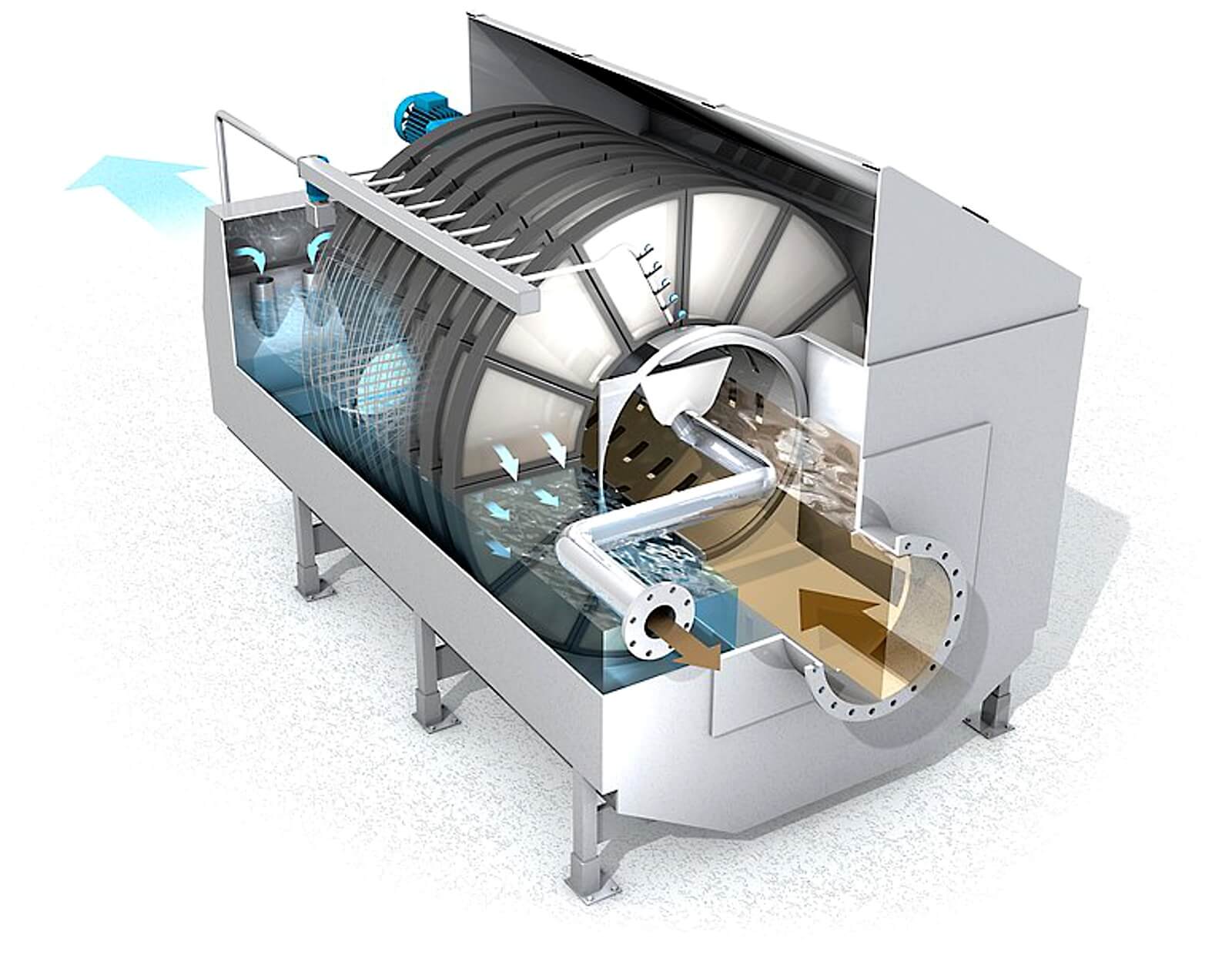

In principle, the entire HUBER product portfolio is used, but especially the HUBER Dissolved Air Flotation Plant HDF, the HUBER Screw Press Q-PRESS®, as well as the HUBER Disc Filter RoDisc® and the HUBER Pile Cloth Media Filter RotaFilt®.