Wastewater Treatment Plants

Products and solutions for efficient wastewater and sewage sludge treatment

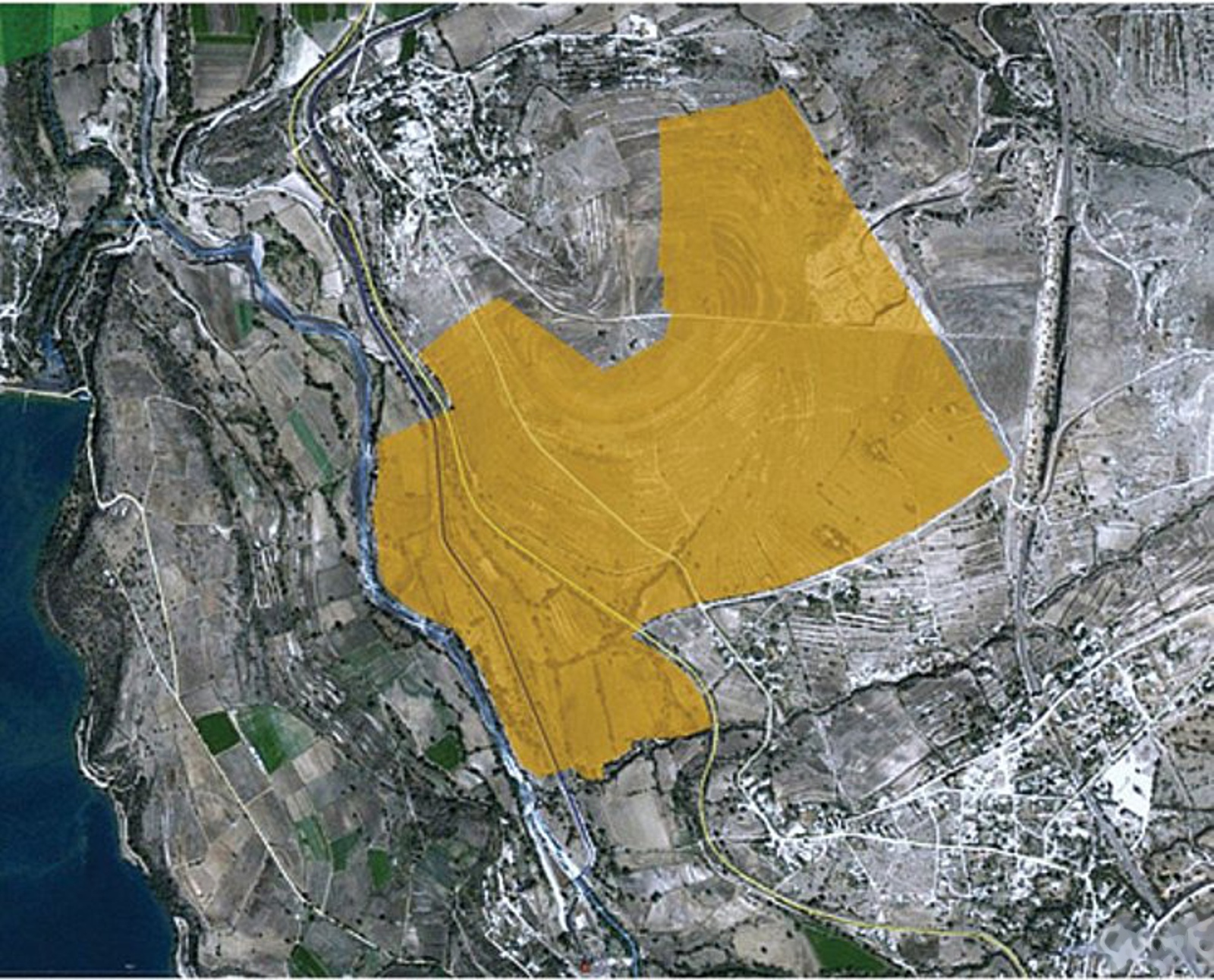

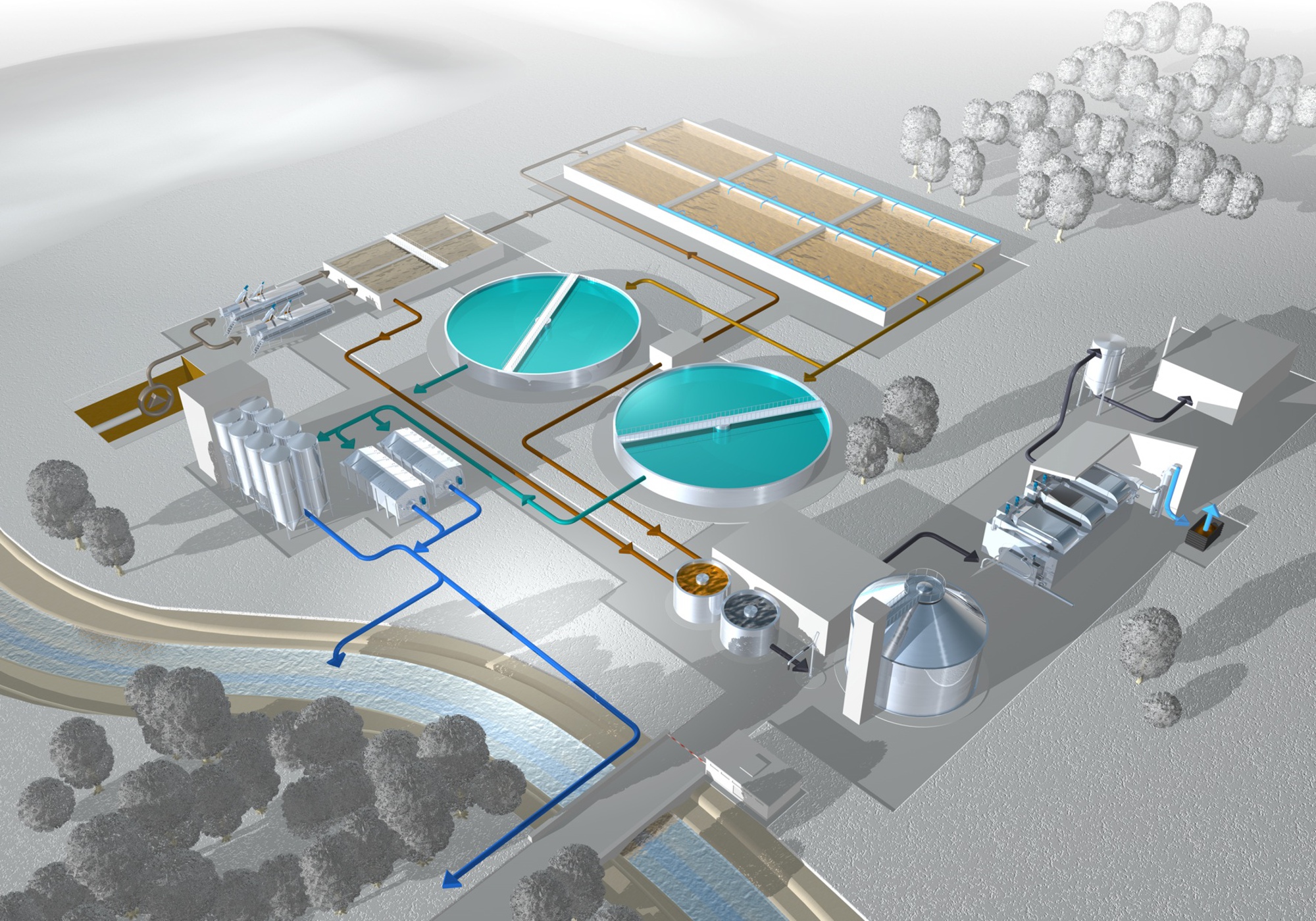

We are experts in providing machines and equipment for the various stages of wastewater and sludge treatment on sewage treatment plants. With our plants and machines we can offer reliable solutions for any size of sewage treatment plant. From large centralized wastewater treatment plants to small decentralized sewage treatment works, HUBER has the right solution.

HUBER offers various products and solutions for wastewater treatment plants:

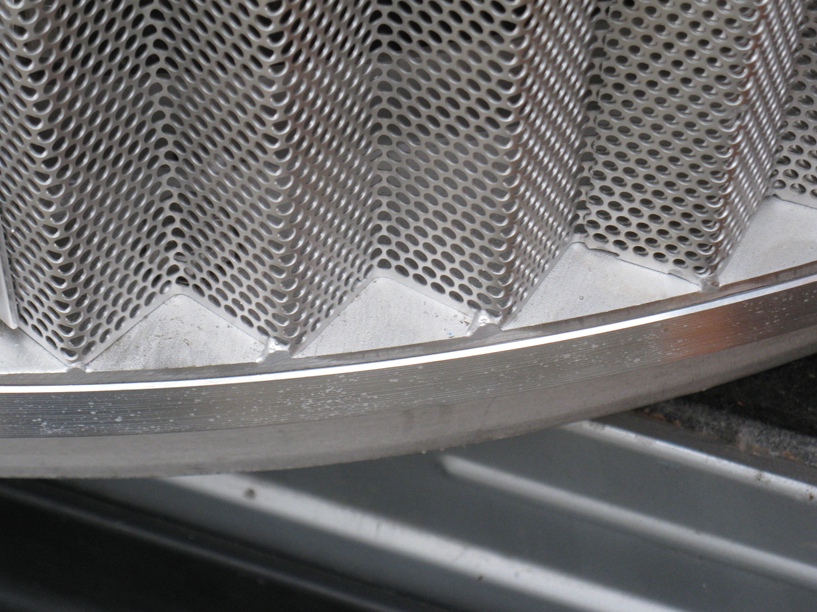

Mechanical pre-treatment: As the first stage of wastewater treatment, operationally reliable mechanical cleaning is the basic prerequisite for all subsequent wastewater treatment stages.

Advanced wastewater treatment: For safe compliance with increased requirements on the quality of the treated wastewater, various processes are available for reducing and eliminating solids, phosphorus, nitrogen and micropollutants (quaternary wastewater treatment).

Screens for pumping stations: Special screens and screening systems ensure the operational safety of pumping stations and lift stations.

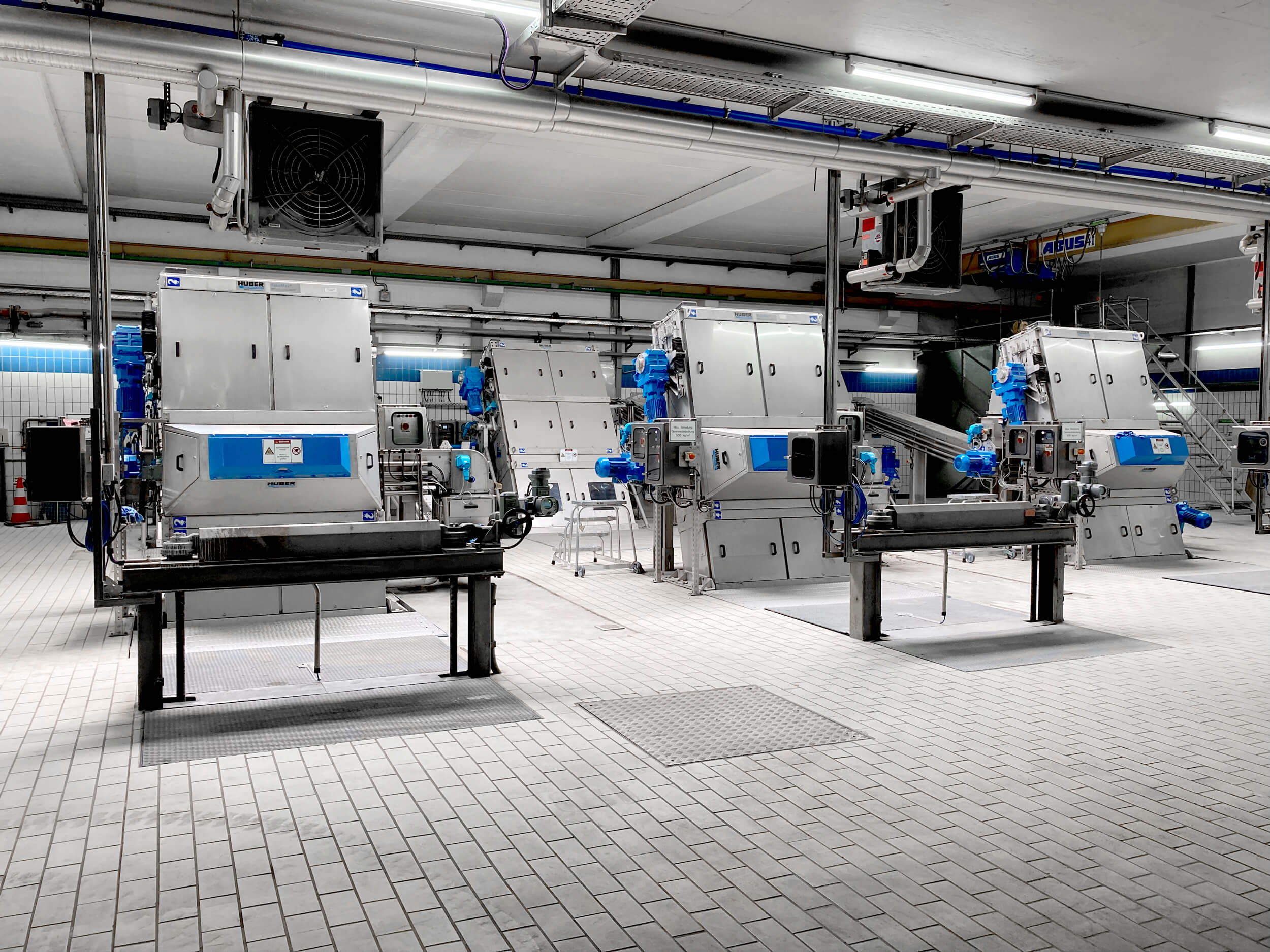

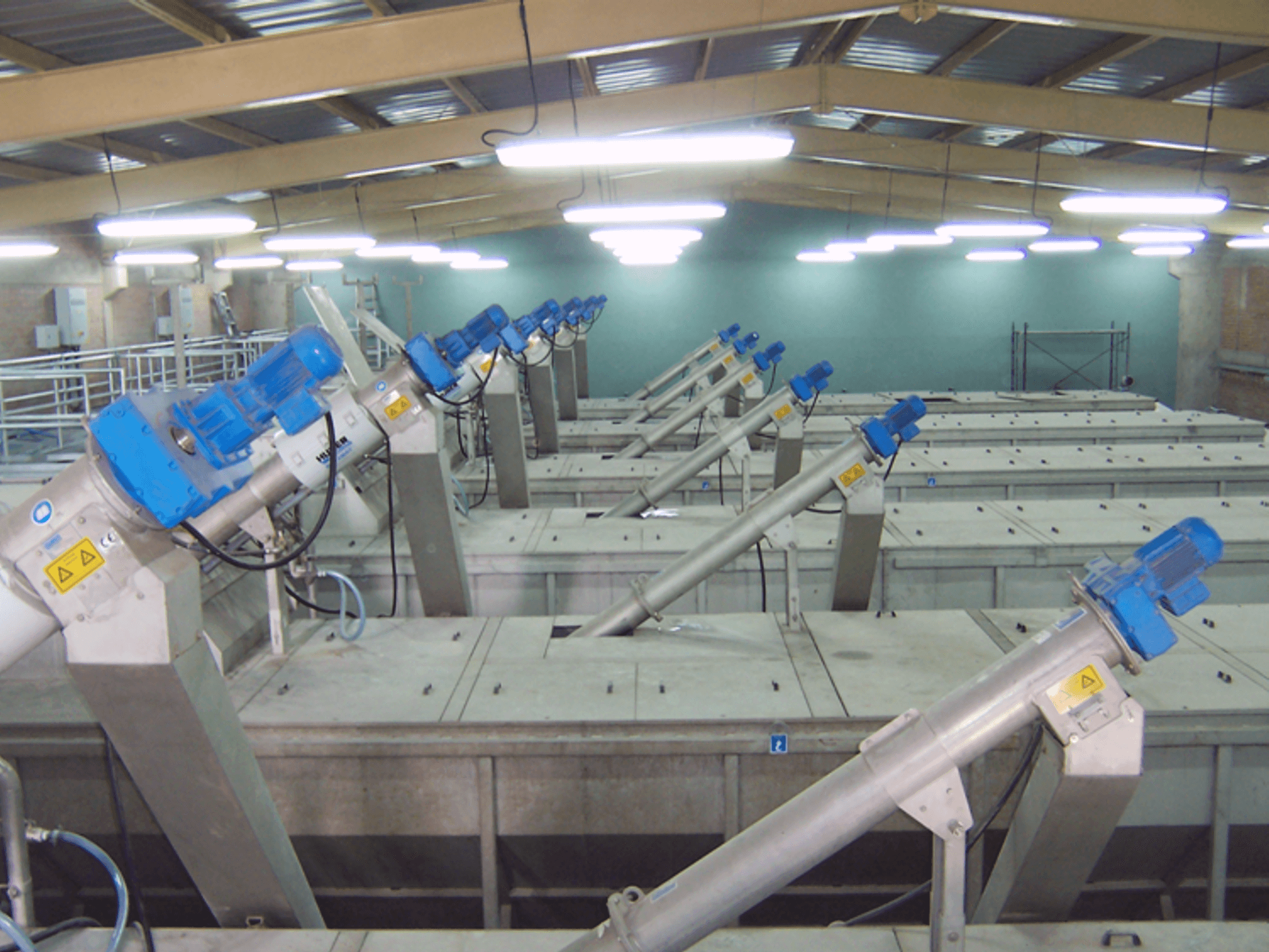

Mechanical treatment of sludge: Removal of coarse material and other solids as well as thickening and dewatering of sludge to reduce volume.

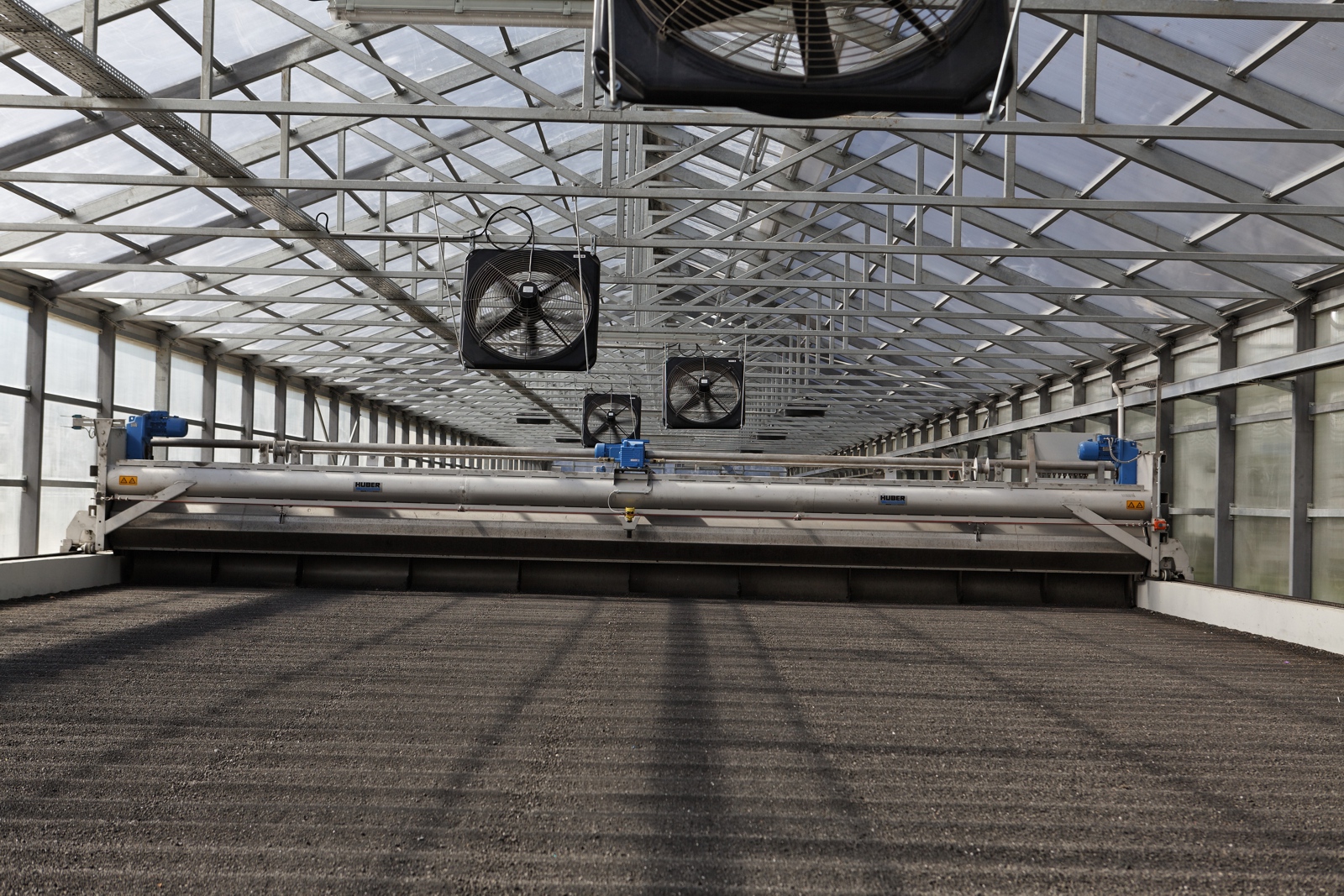

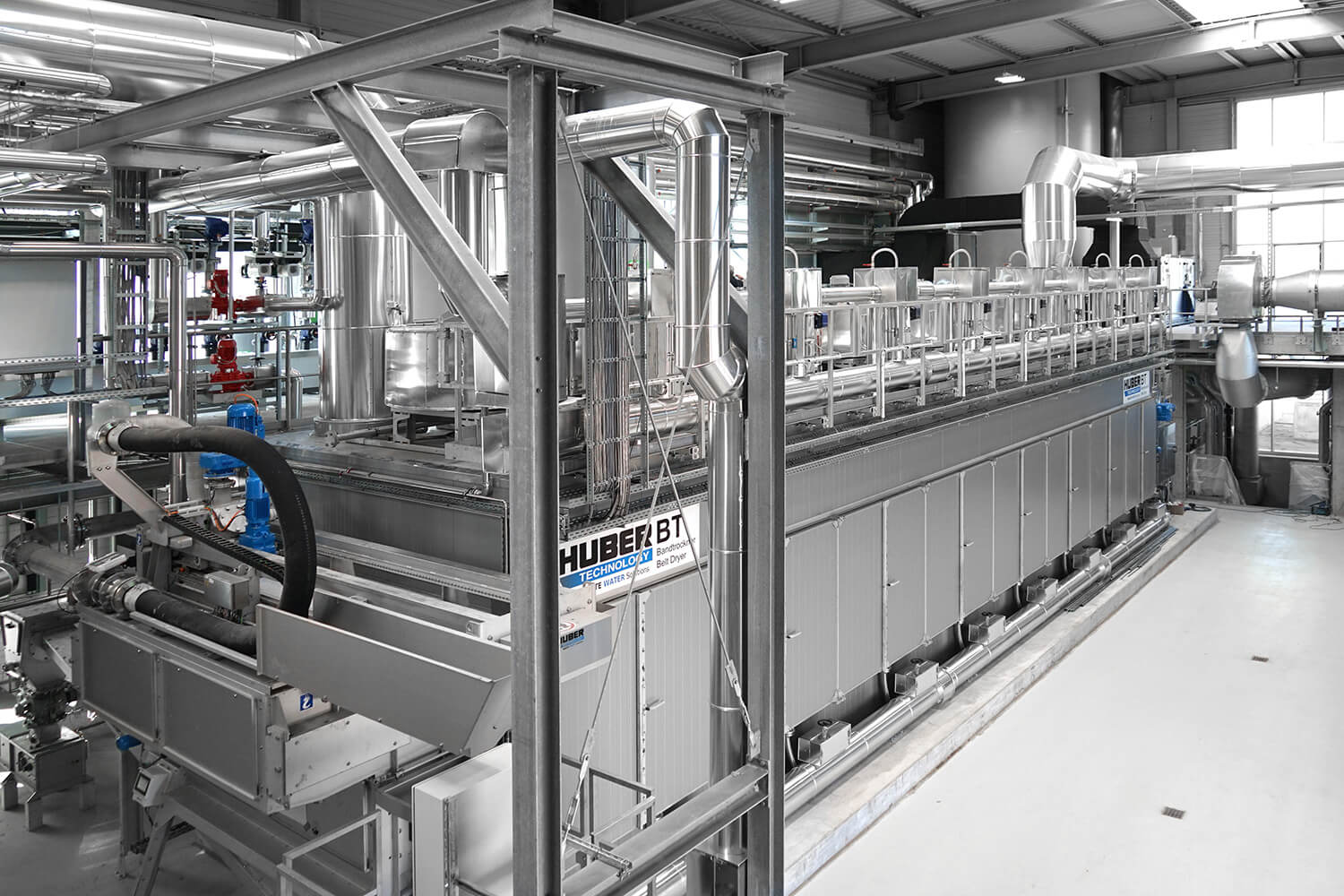

Sludge drying: Thermal processes for partial or complete drying of sludge as a prerequisite for safe and economic disposal or recycling.

Access solutions for manholes and tanks: At wastewater treatment plants, solutions for access into manholes and tanks are required for various applications.

After-sales service: With our HUBER Global Service Team we offer comprehensive and competent customer service that leaves nothing to be desired.

Media