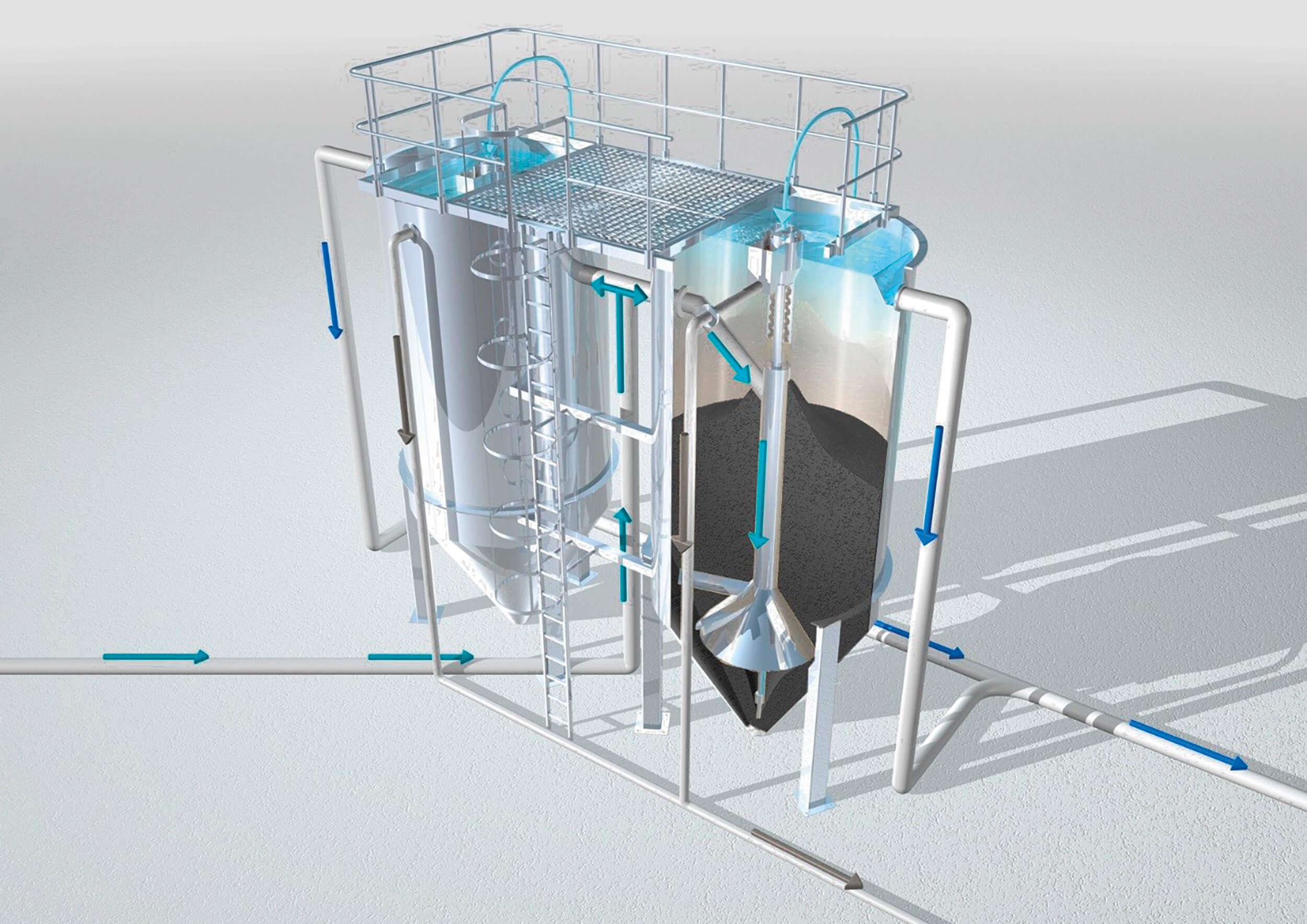

The chemical oxygen demand (sum parameter COD) can often already be reduced to the required quality for discharge into the sewer by chemical-physical treatment (CP treatment). Furthermore, CP treatment is the typical pre-treatment before anaerobic or aerobic wastewater treatment. In any case, the COD retention or reduction can be determined in advance by laboratory or pilot tests.

Reliably Comply with Discharge Limits

Process Technology

HUBER solutions for reliable compliance with discharge limits

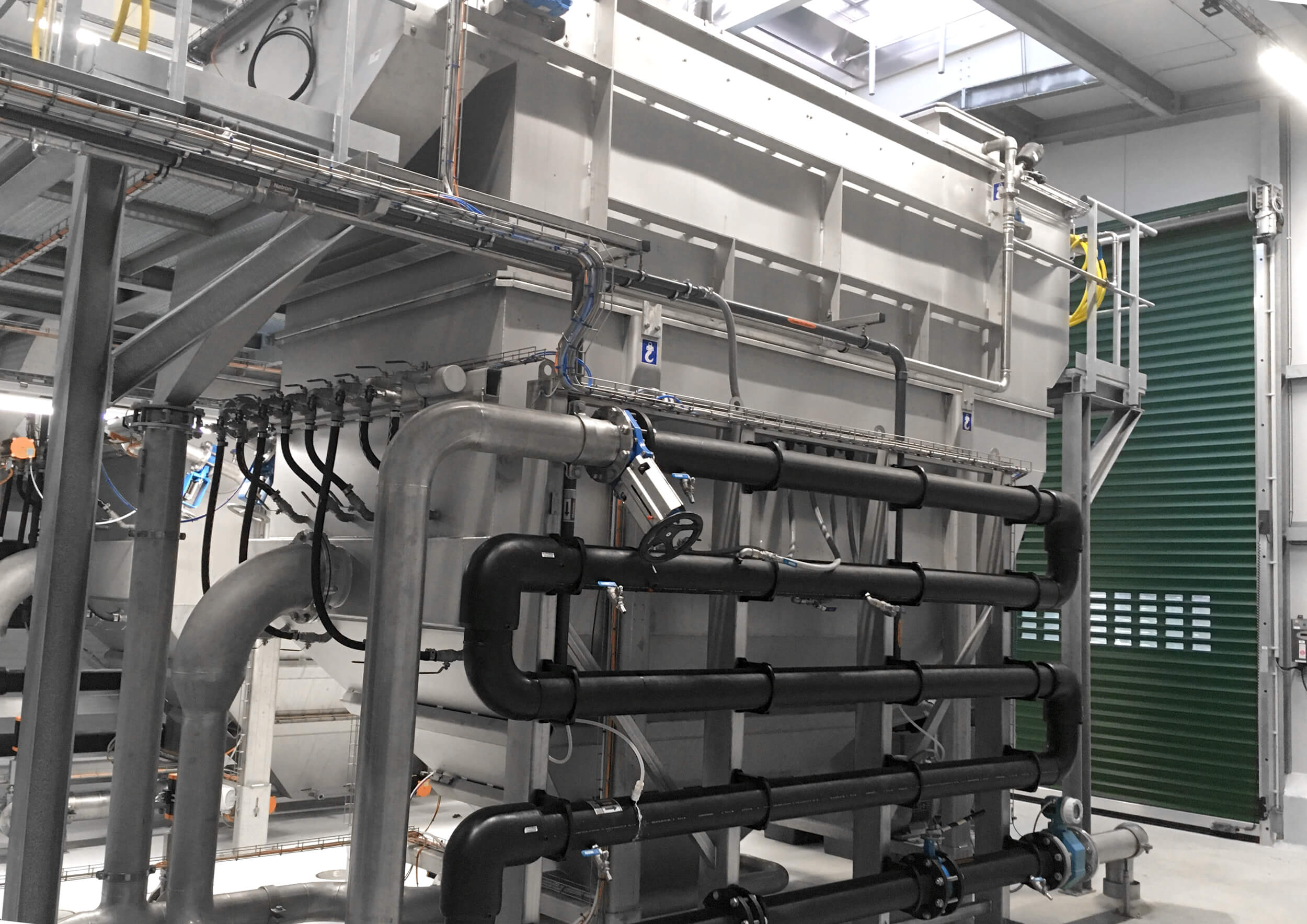

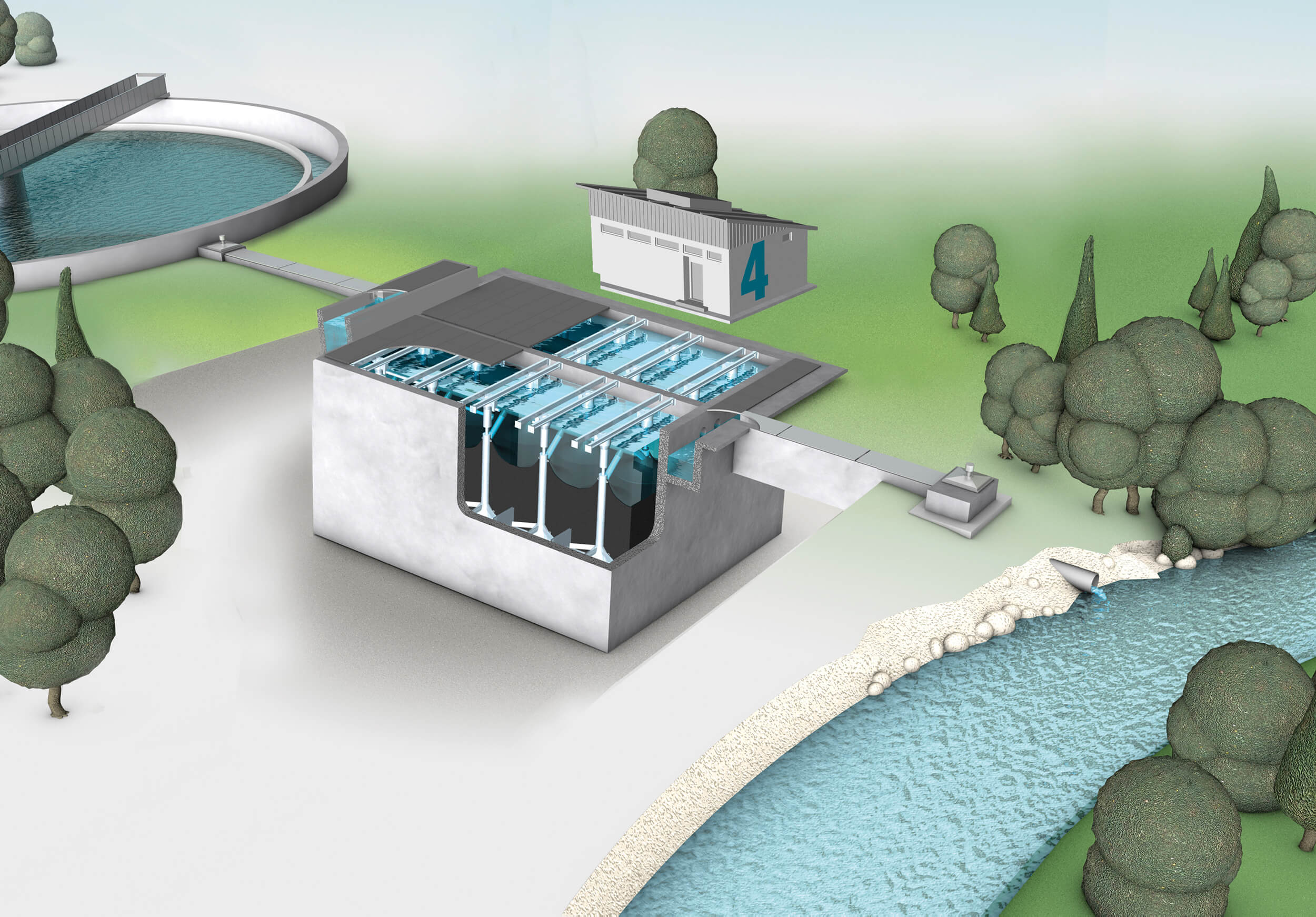

For the upgrading of industrial wastewater treatment systems, HUBER offers the right customised machine and technology for the specific task:

Prevent sludge drift and increase COD reduction:

Increase the biological treatment capacity (full or partial flow):

Phosphorus elimination:

Solids retention and solids polishing:

Reduction and elimination of micropollutants:

Products