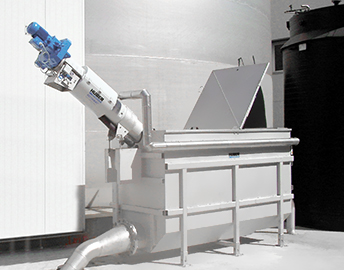

A successful system for 45 years: the innovation and diversity of the HUBER ROTAMAT® machines

Over 9,000 machines in use

Today, over 9,000 machines in various designs are in use in a wide range of areas and industries. Despite our many years of success, we are committed to innovation and renewal, ensuring that we always offer our customers the best possible solutions.

Adjustable perforated plate: manufacturing and customer benefits

All of the machines described above have a trough installed in the screen basket area in which the screenings are collected. Until now, this has been manufactured as a permanently welded perforated plate. The adjustable perforated plate offers considerable advantages in the manufacturing process. This allows the basket area to be adjusted more precisely and easily to the screw conveyor.

Process engineering advantages

This simplifies manufacturing and offers process engineering advantages for our customers. The possibility to adjust the perforated plate more effectively makes screenings conveying even more efficient in operation. Our customers have found that wear can occur on the screw shaft after years of use. With the adjustable perforated plate, this area can be readjusted to extend the machine's service life and increase efficiency.

Adjustable slider: adaptable to specific requirements

The adjustable slider in the machine’s discharge zone has already been successfully implemented in large machines. However, our customers' requirements vary, as does the composition of the screenings, which leads to different degrees of dewatering. The adjustable slider now allows for optimal adjustment to individual situations and levels of dewatering on our smaller machines, too. This enables a tailor-made solution for each customer and helps increase operational efficiency.

Always at the cutting edge

Through continuous innovation and adaptation to our customers' needs, we always remain at the cutting edge and offer solutions that meet the highest requirements. Even after 45 years, we continue to optimise our ROTAMAT® systems and adapt them to meet our customers' ever-changing needs.

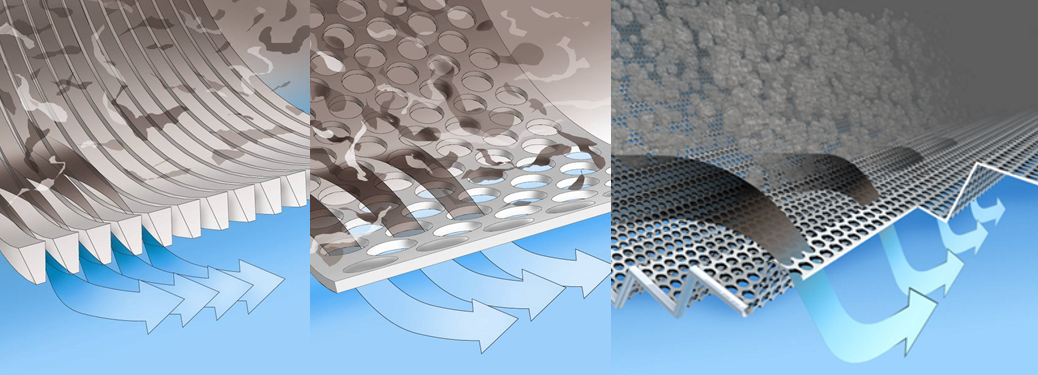

The success story of the HUBER ROTAMAT® machine family began 45 years ago. The patent for the HUBER Fine Screen ROTAMAT® Ro1 was filed at that time, and the ROTAMAT® family has continued to prove itself ever since through continuous innovation and adaptation. The patent described a combination of screening, dewatering, compaction and transport. Over the years, further variants of the Ro1 system, which is equipped with a screen basket and a rake, have been developed. These include the Ro2 with a rotating wedge wire basket, the RPPS, which has a perforated plate screen basket, and the latest variant, the ROTAMAT® STAR with a folded perforated plate screen basket.