The HUBER GritWolf® makes old grit channels look like new

An alternative for ageing scraper bridges.

They work constantly, know no weekends and are exposed to wind and rain. They are familiar with wear and corrosion and are grateful for a few drops of lubricating oil. We are talking about the scraper bridges of grit channels.

When the ravages of time take their toll

At some point, after what feels like two sewage works operator’s lifetimes, the time comes when this ‘vehicle’ is no longer fit for purpose. The concrete of the grit channel could certainly withstand the same amount of time again, but the machinery has had its day.

Complicated replacement

Now good advice is hard to come by, because replacing an old bridge scraper is difficult due to availability and price. In addition, these systems, whether blade or suction scrapers, have the negative habit of causing problems with the submerged ‘transfer’ device (blade/pump). Excessive running times are the consequence if you want to avoid clogged pumps.

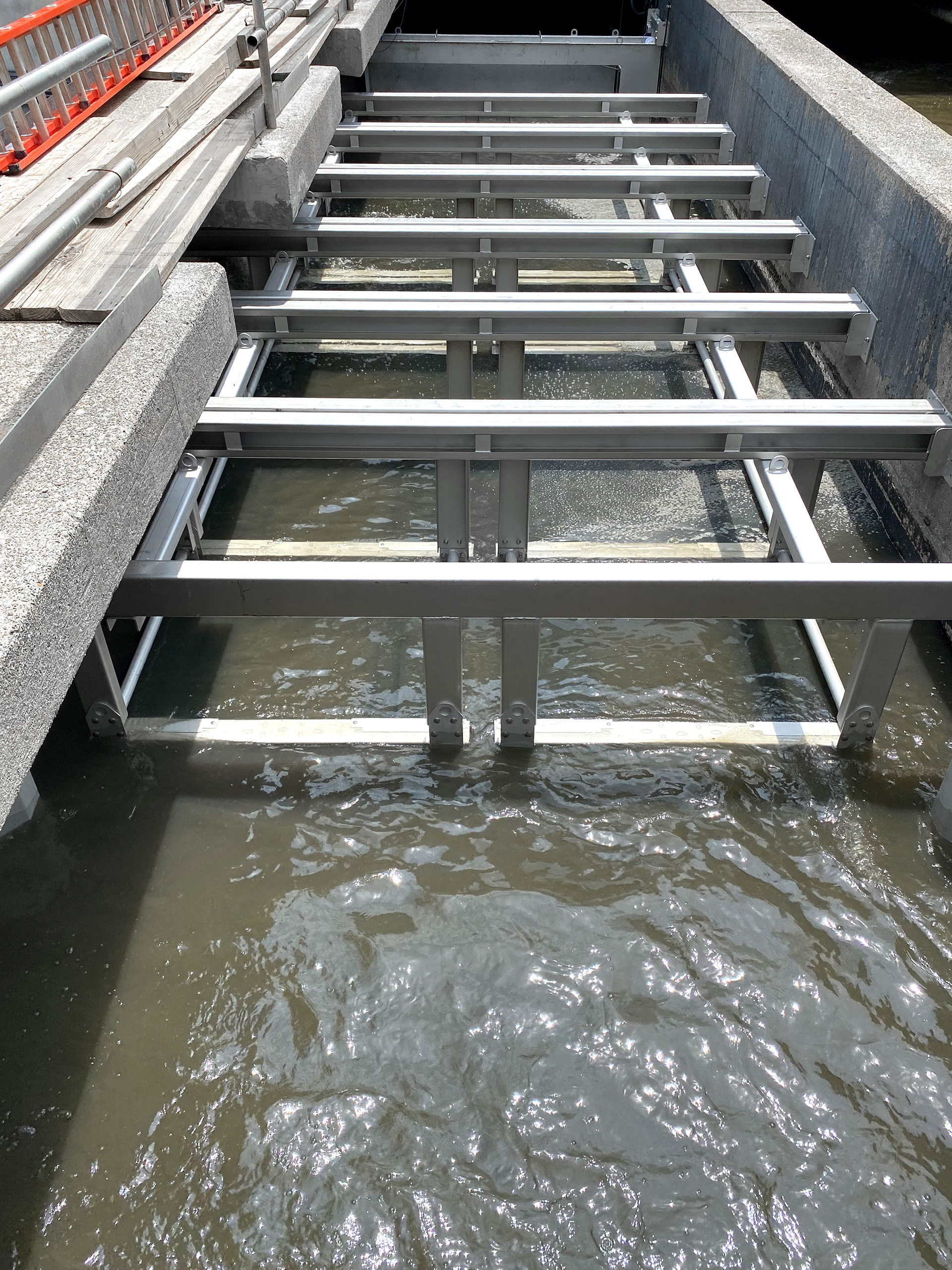

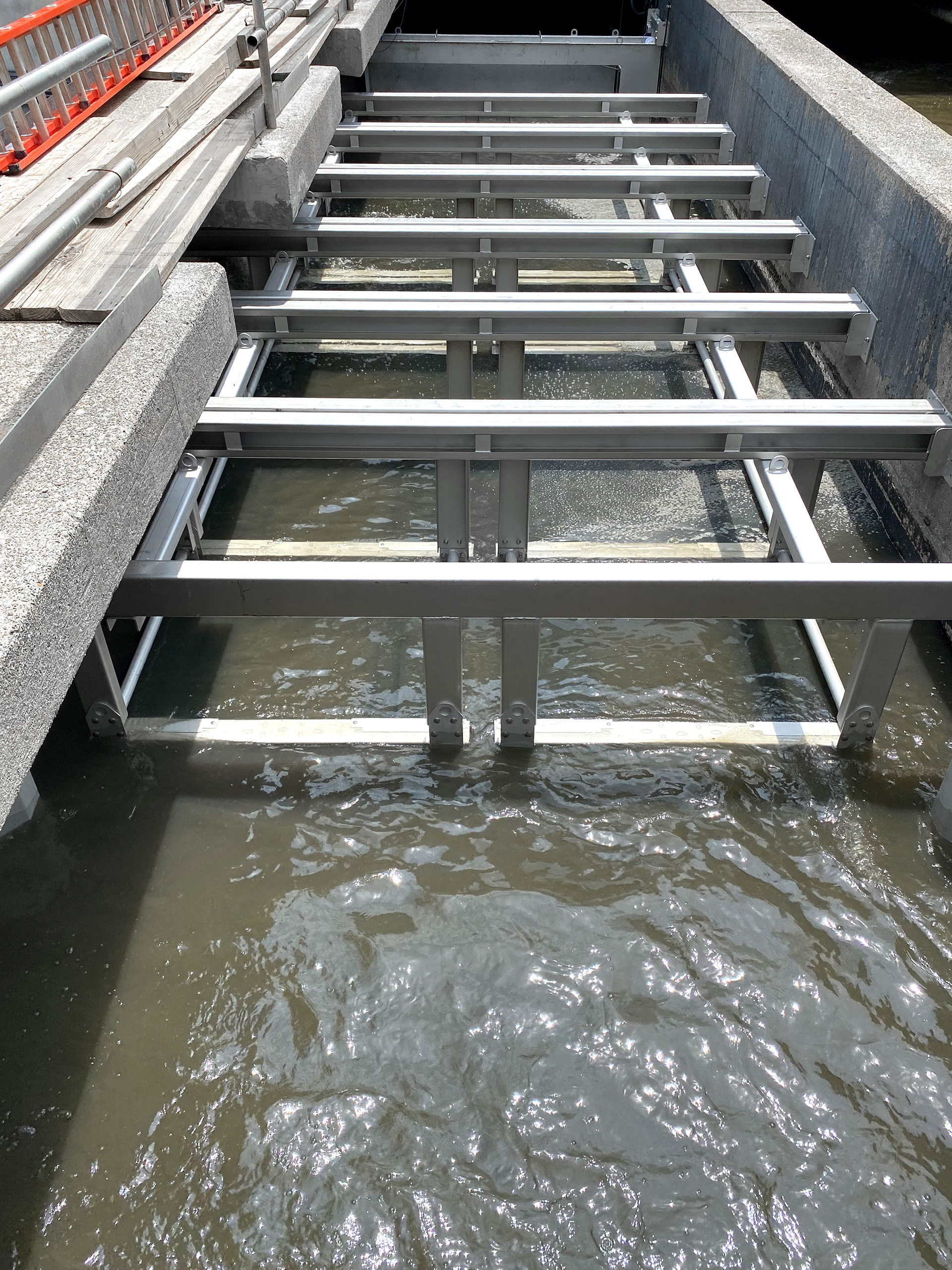

Efficient solution: HUBER Grit Trap GritWolf®

A good solution in case X is the underwater scraper of the HUBER GritWolf® The scraping unit consists of a horizontal screw conveyor that transports the grit separated in the grit channel towards the grit pump. Due to the low speed, the grit is evenly dosed into the inlet area of the pump, which in turn benefits from low wear and reliable operation. If flushing surges cause large amounts of grit to accumulate in the grit channel for a short period of time, the screw reliably works through the pile without increasing the running time.

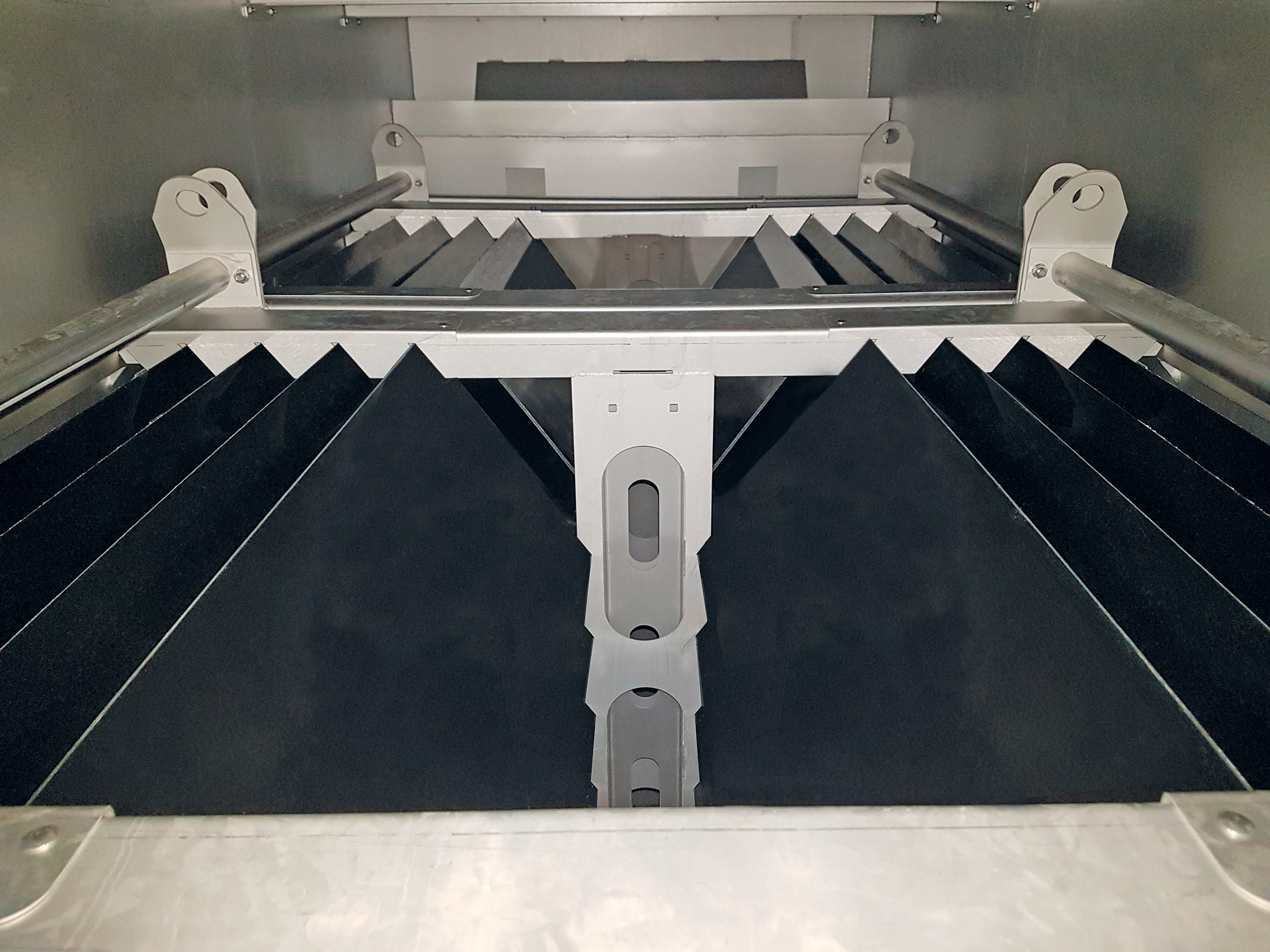

More power with lamella packs

Ageing grit chambers with insufficient grit separation due to increased wastewater volumes can be retrofitted with additional lamella packs from the HUBER GritWolf®. The lamellae provide more settling surface for the grit, so that even ‘undersized’ grit channels can achieve satisfactory grit separation.

Energy savings

The use of lamellae eliminates the need for grit channel aeration, thereby removing a major energy guzzler and contributing to the energy self-sufficiency of a sewage treatment plant. Air, the greatest enemy of fine grit separation, is successfully shown the ‘red card’. The grit trap material becomes finer-grained and the proportion of organic matter also increases. A well-functioning grit washing plant is the right answer to this mixture of solids.

Targeted removal of floating matter

When the air is turned off, floating and grease-like matter collects on the surface of the grit chamber and is transported to the end of the chamber by the flow. There, it can be retained by a baffle plate and removed in a targeted manner by the grease removal paddle of the HUBER GritWolf® and sent for recycling.

Sustainable grit chamber technology

In summary, the use of GritWolf® components simplifies grit removal, improves grit separation and ensures the safe removal of floating matter. As there is no more scraper bridge or ventilation, the entire grit chamber can be covered, putting an end to annoying odour emissions.