New product: HUBER Cold Air Dryer HPS

HUBER is expanding its product portfolio with another dryer for municipal and industrial sewage sludge. This is an innovative cold air dryer with heat pump technology that has been specially developed for smaller applications. The HUBER Cold Air Dryer HPS offers an efficient solution for reducing the amount of sludge to be disposed of and is ideal for plants where no waste heat sources (e.g. from CHP or energy from wastewater) are available.

HPS – what does it stand for and how does the dryer work?

The abbreviation HPS stands for ‘Heat Pump System’. The HUBER cold air dryer uses a heat pump to condition the drying air and thus effectively dry sewage sludge. Unlike conventional drying systems, which rely on waste heat, this dryer generates its heat exclusively from electrical energy. The air flow circulates in a circle and is first cooled down significantly and dehumidified via a cooler, then reheated and conveyed into the drying chamber by fans, much like a tumble dryer at home. In the dryer, the dry, warm air flows through the belts loaded with sewage sludge and absorbs its moisture. The air then returns to the cooler, where it is dehumidified again. The process begins anew with the heating and conveyance into the drying chamber.

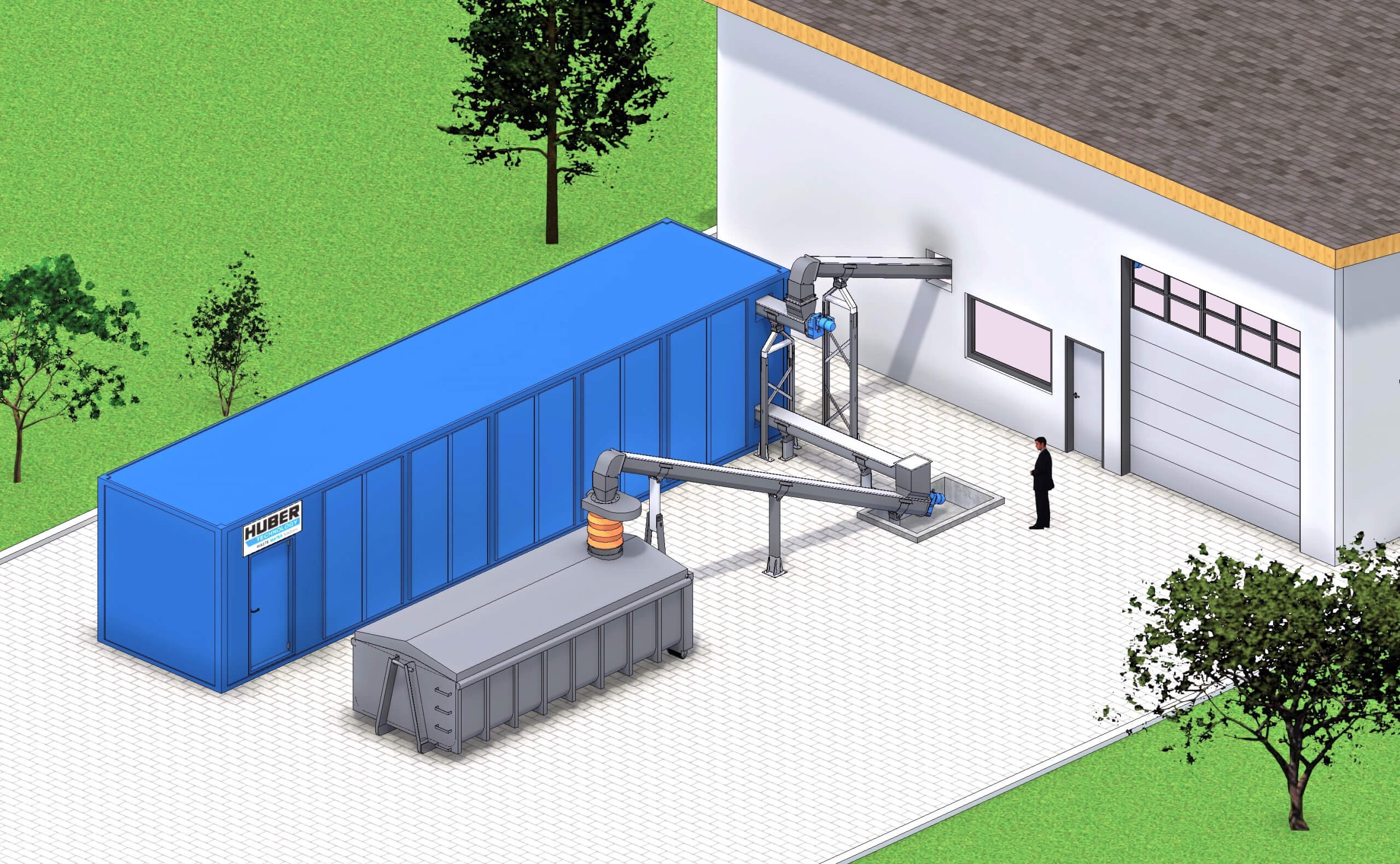

Turnkey system in a container

The dryer has been developed according to the ‘plug and play’ principle and requires as little effort as possible on the construction site. The dryer is fully assembled in the container and delivered with its electrical systems already tested. This means that only the media supply for electricity, condensate drainage, cooling water and sludge supply and removal need to be established. This eliminates the need for time-consuming and costly installation of the dryer at the customer's premises. If a hall or similar facility is available, the dryer can of course also be installed in the building without a container.

Modular design

The HUBER Cold Air Dryer HPS is designed for wastewater treatment plants with a size of up to 50,000 PE or an annual sludge production of max. 3,000 t. Depending on the amount of water evaporation required, between one and five drying modules can be used. By using these standardised modules, the customer receives a cost-effective, high-quality machine in the usual HUBER quality.

Conclusion

The HUBER Cold Air Dryer HPS is particularly suitable for use in combination with a HUBER Screw Press on sewage treatment plants up to 50,000 PE. The combination with a regenerative electrical energy source, such as a PV system with energy storage, represents another important step towards climate neutrality and a positive CO2 balance.