Flexible Disc Thickener on WWTP Waging

HUBER Sludge Thickener excels for its operating reliability and energy efficiency with thickening primary and surplus sludge in automatic mode!

In summer 2015, Gemeindewerke Waging (municipal utilities) in the Bavarian Chiemgau district were desperately looking for an energy-efficient, high-performance sludge thickening plant.

They wanted a new energy-efficient and well-proven technical solution to replace their old centrifuge which consumed too much energy.

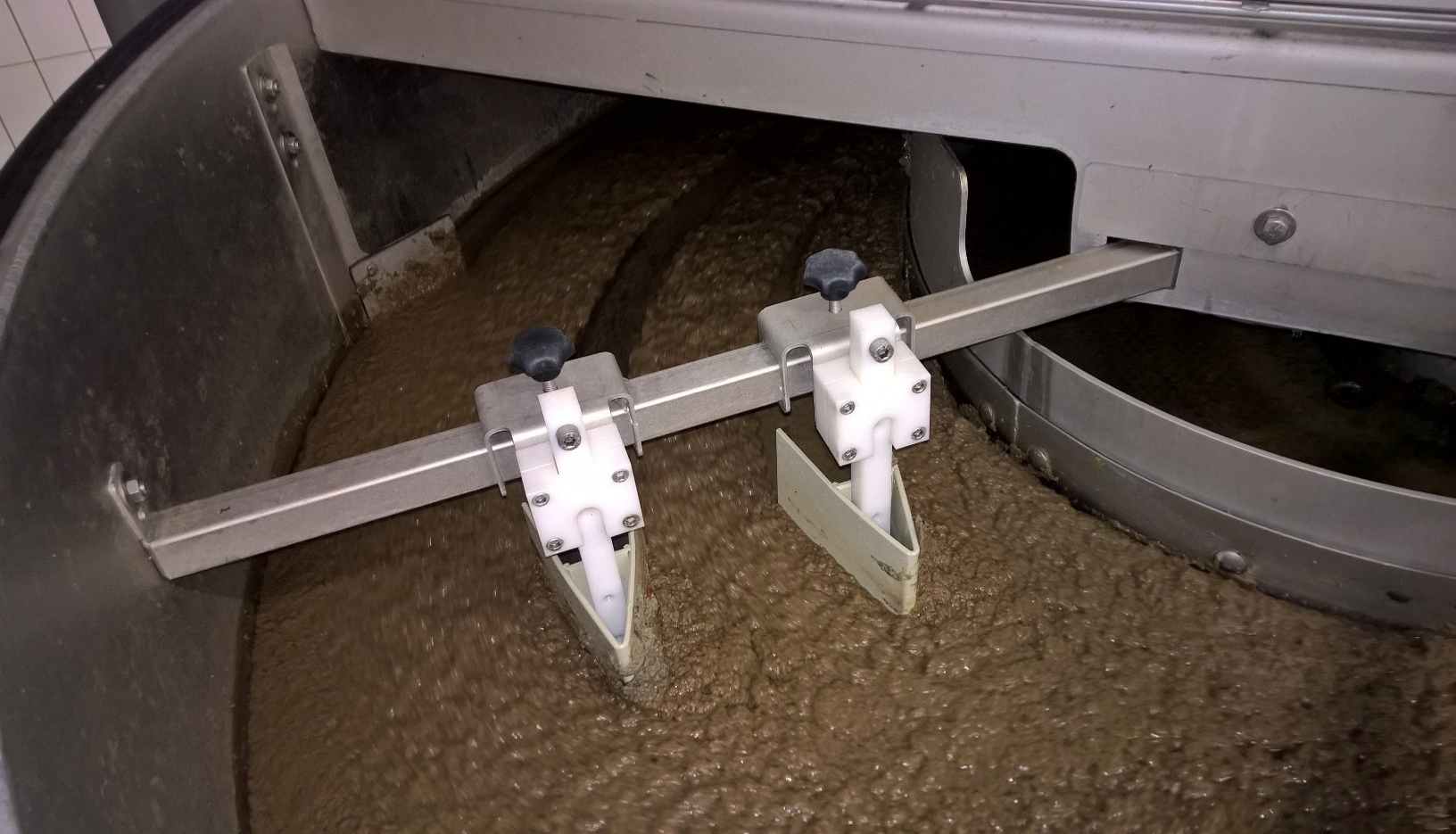

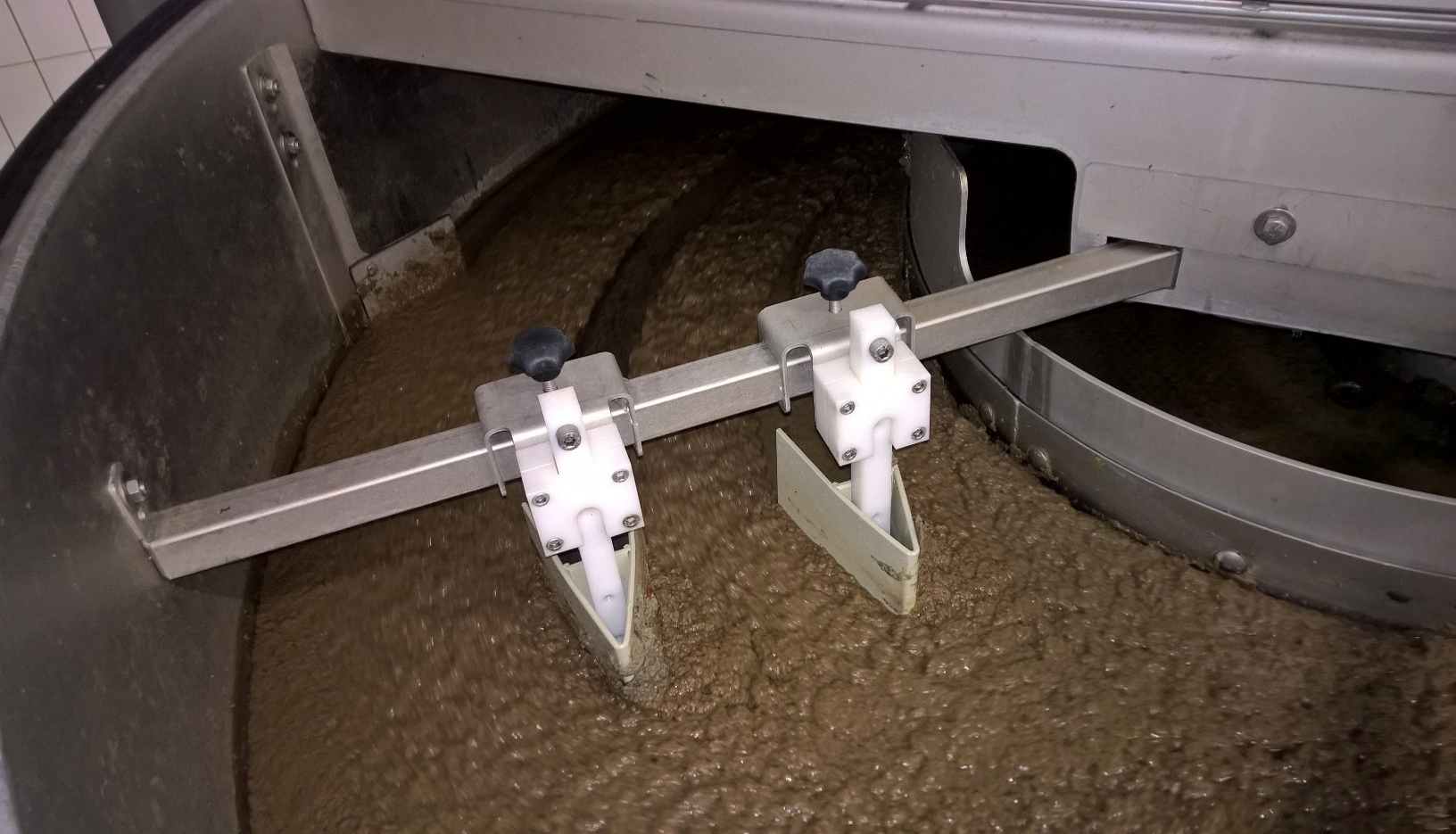

Before they decided to buy a new system they tested a HUBER Disc Thickener S-DISC installed in a tank on their sewage treatment plant at Waging. Surplus sludge and separately also primary sludge was thickened in the trials with the aim to optimize digester capacity, gas yield and sludge handling in the overall process on site.

After evaluation of all test results it turned out that the excess sludge with 0.6% DS was thickened to > 6% and the primary sludge with 1.8% DS to > 8% by automatic time-lagged operation. To ensure automated operation the initial DS contents of the different sludges is determined so that the plant parameters of the automatic operation system can adjust themselves to varying sludge qualities.

The decisive factors in favour of the HUBER Disc Thickener were that our system is robust, reliable and insensitive and demonstrated convincingly its operation efficiency during the test phase.

The HUBER Disc Thickener S-DISC is a slowly rotating disc construction that is installed at an angle inside a closed stainless steel tank. The filter disc divides the tank into three areas: solids feeding area, thickening area (supported by chicanes), and sludge discharge area. The pre-flocculated sludge flows from the flocculation reactor onto the filter disc surface and the filtrate set free flows through a mesh and runs off. The remaining sludge is thickened to the requested solids concentration and in the upper section of the disc thickener transported into the thick sludge tank by a scraper system. The major advantage of the HUBER Disc Thickener is that a very high efficiency of sludge thickening can be achieved with low investment and operating costs (see operating results).

On WWTP Waging the HUBER Disc Thickener S-DISC is installed in the basement of the operational building. This location has the advantage that the primary sludge and surplus sludge can be taken centrally and the generated thick sludge directly fed to the digester.

We would like to take this opportunity to thank Gemeindewerke Waging and the operating staff on WWTP Waging for the problem-free execution of the project and wish them also for the future a failure-free plant operation with the HUBER Disc Thickener.

Operating results at the time of plant start-up achieved with thickening surplus and primary sludge:

| Type of sludge | Surplus sludge | Primary sludge |

| Sludge index | 120 | |

| oDS | 78 % | |

| initial DS % | 1.0 | 1.8 |

| Throughput capacity m³/h | 30 | 20 |

| Throughput capacity kg/h | 250 | 360 |

| Final DS % | 6 – 8 | 6 – 10 |

| Polymer consumption g/kg DS | 3 | 3 |

| Separation degree % | > 99 | > 99 |

| Rotary disc speed rpm | 1.5 – 3 | 3 |